Why Samtop Accepts 3D-Only Submissions — and How We Convert Them into Production-Ready Displays

By Yan Luo, Founder & Engineering Lead, Samtop Display

Table of Contents

Yes — Samtop accepts 3D-only display design files (e.g. .STP, .SKP, .3DM), and transforms them into complete engineering packages: including 2D CNC files, BOMs, and assembly guides. No separate CAD draft required.

You’ve already created a full 3D model in SketchUp, Rhino, or Fusion. Now you’re wondering:

“Do I also need to prepare full 2D CAD files for production?”

Many factories can’t work directly from 3D visuals — leading to:

- Missed cut lines or tolerances

- Rework delays

- Miscommunication between design & production

- Uncertainty during approval

At Samtop, we specialize in 3D-to-production engineering.

You send us the model — we do the rest: from CNC file generation to assembly logic, even for incomplete visuals.

🔧 What Happens When You Send Us a 3D File

| Step | What We Do | Outcome |

|---|---|---|

| 📥 Import | Open in SolidWorks / Rhino / Fusion | File cleaned, scaled, analyzed |

| 📏 Analyze | Extract dimensions, slot geometry, material layers | DFM-ready breakdown |

| 🔩 Convert | Flatten key panels for CNC / laser cutting | 2D .DXF / .DWG created |

| 🔧 Engineer | Add fixings, LED routing, cable paths | Full assembly logic generated |

| 🧪 Simulate | Weight, tolerance, and stress points reviewed | Production test plan |

| 🛠️ Output | Create drawings, BOM, exploded views | Client-ready engineering set |

📐 Accepted File Formats

| Format | Software | Notes |

|---|---|---|

.STP / .STEP | SolidWorks, Fusion | ✅ Most stable, preferred |

.3DM | Rhino | ✅ Common in agency submissions |

.SKP | SketchUp | ⚠️ Often lacks structure – we rebuild internally |

.IGES | CATIA, Rhino | ✅ Good for surface-based designs |

.FBX / .OBJ | Blender / 3ds Max | ⚠️ Needs cleanup & scaling |

.SLDPRT | SolidWorks | ✅ Parametric, fast approval |

Don’t worry if you’re unsure — we’ll review and confirm compatibility within 24 hours.

🧰 When 2D CAD Is Still Needed — And How We Handle It

While 3D defines the shape, it rarely defines:

- 🔩 Screw placement

- ✂️ Cutting path for CNC/laser

- 🧱 Assembly joints & part nesting

- 📦 Flat-pack configuration

- ⚡ Wiring + component access

💡 That’s why our in-house team converts your 3D file into a full production tech pack:

- .DXF/.DWG for manufacturing

- PDF exploded views for approval

- Nesting layout for material optimization

- Golden sample photo specs for QC

✅ All included — no separate drafting fee.

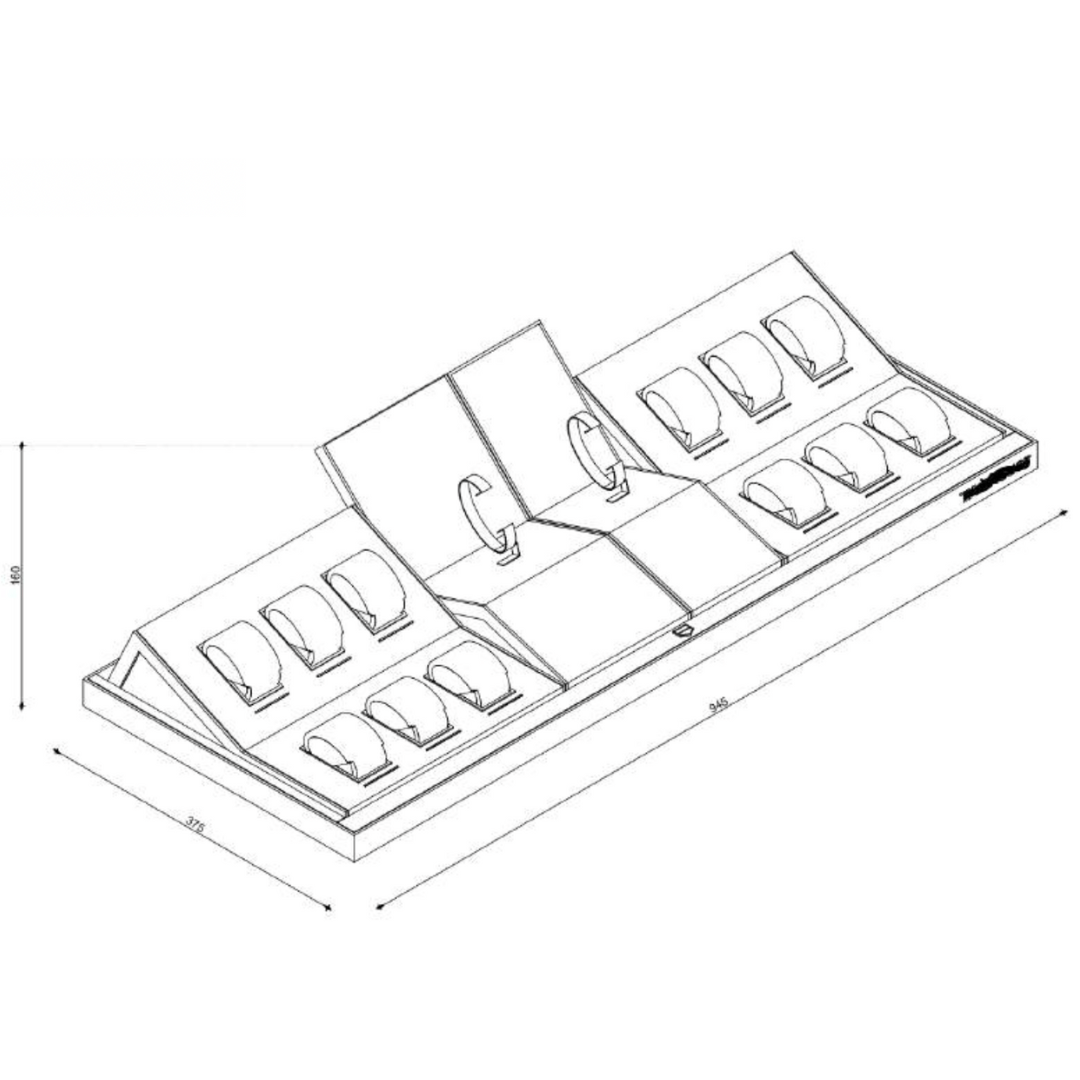

🧪 Case Study: From SketchUp to Shipment in 5 Days

Client: EU creative agency

Input: SketchUp file with screenshot sizes

Goal: Fragrance tester tray with LED, PU base, magnetic signage

Problem: No cut files, no engineering details

Samtop Solution:

- Rebuilt geometry in Rhino → engineered in SolidWorks

- Added cable channels + modular tray logic

- Created full DWG / DXF / BOM set in 5 days

- Prototype approved → mass production shipped to 4 countries

✅ 22% lighter structure

✅ 0 rework

✅ Reusable base for next campaign

🤔 What If My 3D Model Is Incomplete?

We fill in the gaps.

Send us:

- 📸 Moodboard / photos

- ✏️ Sketch with rough sizes

- 🧱 Material targets (e.g. “PU base + acrylic tray”)

- 💡 Function priority (e.g. “LED must be hidden”)

We’ll reverse-engineer it into production logic.

👥 Who This Is For

✅ Creative agencies

✅ Visual merchandising managers

✅ Brand design teams

✅ Procurement teams evaluating manufacturing options

✅ Retail engineering leads

🎯 Conclusion: Send the Vision — We’ll Engineer the Execution

At Samtop, you don’t need to submit perfect 2D tech packs.

We understand design, interpret visuals, and engineer reality — across acrylic, PU, LED, resin, fiberglass, and more.

📬 Send us any of the following to get started:

- 3D model

- Moodboard + sketch

- Reference display photos

📧 [email protected]

🌍 www.samtop.com

Samtop Display — Where Visual Concepts Become Retail-Ready Engineering.