Reduce Freight, Minimize Damage, and Maintain Premium Visuals

By Yan Luo | Founder, Samtop Display

Table of Contents

At Samtop, we engineer display materials not just for looks — but for global shipping. Our material strategy reduces freight by up to 40%, damage by <1%, and ensures consistent quality across countries by selecting lightweight, durable, flat-pack-ready options.

Designing a stunning retail display is one challenge.

Getting it to 5+ countries intact, affordable, and on-brand is another.

Most display failures come not from poor design — but poor material choice for shipping:

- Too heavy for air

- Too fragile for vibration

- Too bulky for efficient palletization

At Samtop, we recommend materials that are visually premium and globally shippable — engineered for:

- 💸 Freight cost savings

- 🚚 Transit durability

- 🧩 Modular assembly

- ✨ In-store impact

✈️ Factors That Drive Material Choice in Global Shipping

| Factor | Why It Matters |

|---|---|

| 📦 Weight | Impacts air freight cost and local handling effort |

| 💥 Fragility | Higher risk = more damage, more returns |

| 🪛 Assembly method | Flat-pack = fewer damages, lower shipping volume |

| 📐 Volume | Units per pallet/container drive cost efficiency |

| 🌡️ Climate | Avoid warping or color shift in humid or hot markets |

| 🧱 Finish durability | Rubbing, vibration, stacking can ruin fragile surfaces |

🧱 Our Most Recommended Materials — Ranked by Shipping Fit

1️⃣ Acrylic (PMMA)

✅ When Protected Properly

| Pros | Glossy, high-end appearance |

|---|---|

| Cons | Brittle + scratches during shipping |

| Fix | Anti-scratch coating + PE film + ship flat |

📦 Use for: Logo panels, light trays

🚫 Avoid in: Large bonded panels shipped assembled

2️⃣ PU-Wrapped MDF

✅ Versatile and Durable

| Pros | Leather feel, scratch resistant, affordable |

|---|---|

| Cons | Needs edge-sealing in humid climates |

| Fix | Moisture-sealed MDF + high-grade PU + flat-pack design |

📦 Use for: Tester trays, podium bases

✅ Lower weight + better shock resistance

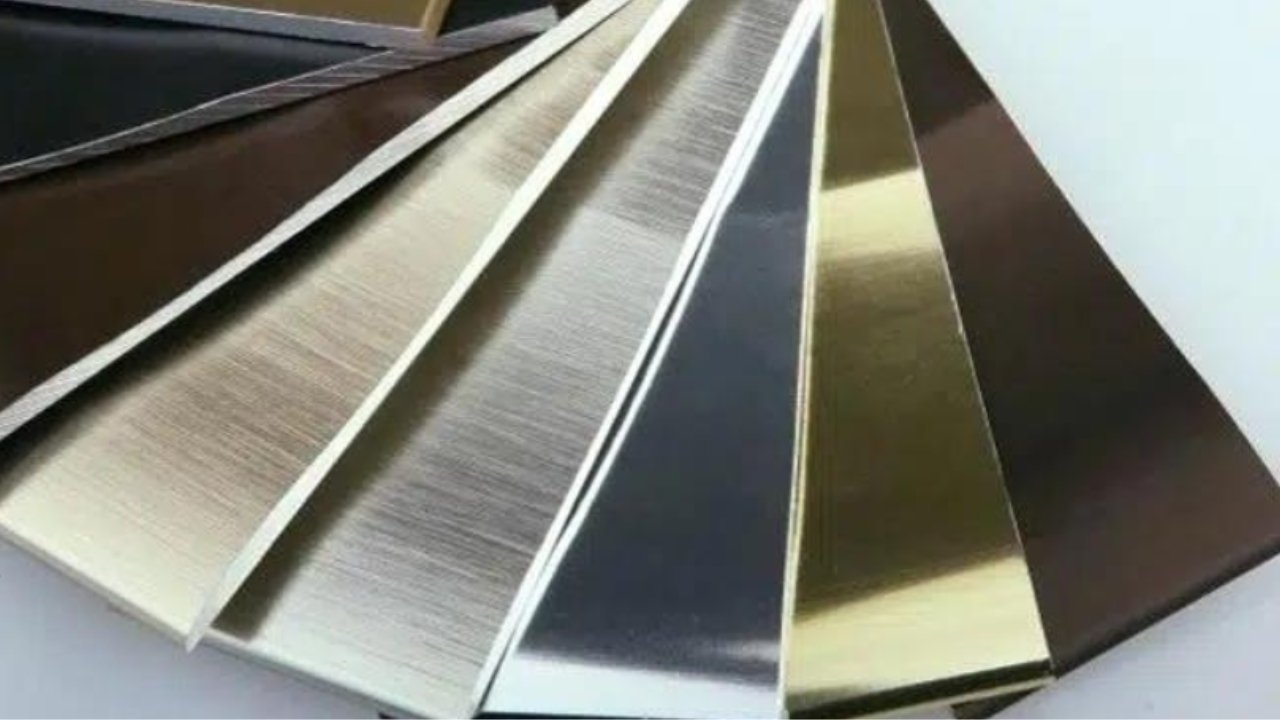

3️⃣ Metal (Aluminum / Steel)

✅ High-End Look, Manageable When Balanced

| Pros | Strong, sleek, luxury perception |

| Cons | Heavy (especially steel), more expensive freight |

| Fix | Use aluminum, combine with light elements (PU, foam, resin) |

📦 Use for: Logo plates, structural frames

✅ Use in modular + detachable components

4️⃣ Fiberglass (FRP)

✅ Ideal for Props, 3D Forms

| Pros | Moldable, strong, light |

| Cons | Requires inner support + good packaging |

| Fix | Foam core + suspension packaging with air buffer |

📦 Use for: Sculptures, window props

🧳 Great for long-haul + multi-point freight

5️⃣ PU Foam + Resin Coated

✅ Ultra-Light, Visually Striking

| Pros | Lightweight + durable + fully customizable |

| Cons | Surface may dent if unprotected |

| Fix | Resin top layer or clear coat for resistance |

📦 Use for: Campaign props, branded shapes

✅ Ships dense + low freight cost

🔄 Flat-Pack Starts at Material Level

Samtop display systems are designed for:

- ✅ Snap-fit acrylic panels

- ✅ Foldable metal frames

- ✅ Slide-in MDF structures

- ✅ Slot-in magnetic signage

💡 One client saved $6,800 on freight by switching from full acrylic to:

PU-wrapped MDF base + foldable aluminum frame + snap-in acrylic face

🧪 Real Case Study: 3-Region Tester Tray Optimization

Client: Global beauty brand

Original Plan: Prebuilt full acrylic tray + back wall

Issues: $12,300 in projected air freight + breakage risk

Samtop Upgrade:

- Tray = PU-wrapped MDF

- Back wall = Slot-in acrylic panel

- Logo = Magnetic strip

- Ship = Flat (2 units per carton)

✅ Results:

- 💰 Freight reduced to $7,200

- 📦 0 units damaged

- 🛠️ Assembled in 8 minutes in-store

👥 Who Should Read This?

- ✅ Procurement sourcing for global campaigns

- ✅ VM professionals designing for overseas installs

- ✅ Creative agencies coordinating international launches

- ✅ Rollout managers under cost + damage pressure

🧭 Samtop’s Material Planning Process

1️⃣ You share:

- Display sketch or CAD

- Target countries + delivery method

- Materials you’re considering

2️⃣ We analyze:

- Freight type (LCL, FCL, express, air)

- Humidity, climate risks

- Fragile finishes, volume per pallet

3️⃣ We recommend:

- ✔️ Material upgrades

- ✔️ Cost vs. damage analysis

- ✔️ Flat-pack or modular structure

- ✔️ Protective packaging + reuse tips

🎯 Conclusion: Materials Are Your First Shipping Decision

💬 Great visuals are expected.

✅ Surviving the journey — that’s the real challenge.

At Samtop, we help clients design displays that:

- ✔️ Impress at retail

- ✔️ Ship with confidence

- ✔️ Reduce cost

- ✔️ Protect your brand image — every km of the way

📧 Planning a global display rollout? Let’s ship smarter.

📩 [email protected]

🌍 www.samtop.com

Samtop Display — Designed for Beauty. Engineered for the World.