By Yan Luo | Samtop Display

Table of Contents

Are You Choosing Display Materials Based on Looks — or Strategy?

The display might look great on-screen, but will it last in-store? Will it ship well? Can it support the weight of your product, and still reflect your brand identity?

Material choice can make or break a POP campaign — and many teams default to what they know (acrylic, MDF) without considering cost, finish, or shopper touchpoints.

At Samtop, we help brands select the right material or hybrid for every display: based on budget, volume, and use environment — from luxury beauty counters to airport FSDUs.

✅ Short Answer (for Google Featured Snippet)

- Acrylic = high-gloss, clean finish for premium displays

- MDF = cost-effective, customizable, smooth for printing

- Metal = structural strength, sleek or industrial look

- Cardboard = budget-friendly, fast for promos or trial kits

- Hybrid = smart visual + structural balance at scale

📌 Choose material based on product weight, store condition, finish quality, and campaign length.

🧠 Let’s Compare the 4 Core Materials in POP Design

Here’s how each performs — and where it shines.

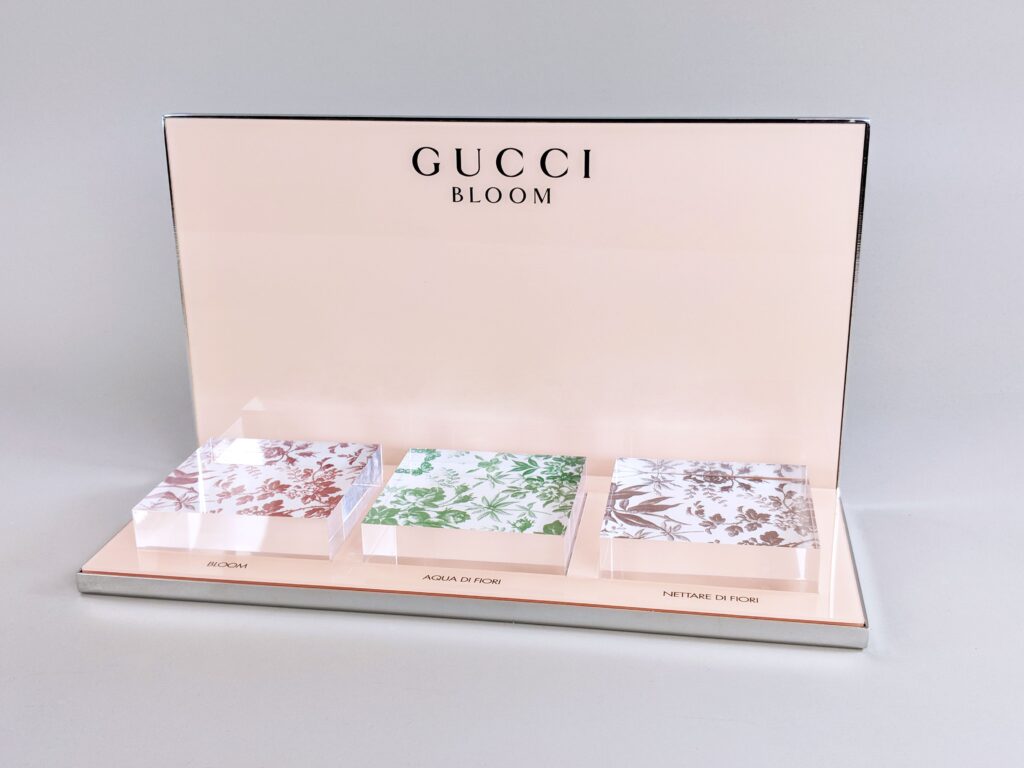

🧪 1. Acrylic: For Visual Clarity and Luxury Tone

| Attribute | Value |

|---|---|

| Finish | Glossy, frosted, mirrored, matte |

| Brand Look | Clean lines, premium, transparent |

| Use Cases | Counter trays, risers, tester units |

| Pros | Light diffusion, scratch-resistant (coated), elegant |

| Cons | Brittle under pressure, medium-high cost |

| Variants | Cast/extruded, colored tints, edge-lit LED |

📌 Best for fragrance glorifiers, skincare tester trays, jewelry risers.

🪵 2. MDF: The Stable Workhorse for Semi-Permanent Installs

| Attribute | Value |

|---|---|

| Finish | Paintable, veneered, UV-printed |

| Brand Look | Solid, versatile, mass retail |

| Use Cases | Floor displays, shelving, bases |

| Pros | Stable, smooth, cost-friendly |

| Cons | Heavy, not water-resistant unless sealed |

| Variants | FSC-certified, PU-coated, laminated MDF |

📌 Best for global rollout kits, mid-term campaigns, beauty walls.

🔩 3. Metal: For Strength and Structure

| Attribute | Value |

|---|---|

| Finish | Powder-coated, brushed, chrome |

| Brand Look | Technical, luxe, long-lasting |

| Use Cases | FSDU frames, watch holders, fixture skeletons |

| Pros | Load-bearing, recyclable, crisp forms |

| Cons | Longer lead time, higher cost, can scratch |

| Variants | Steel, aluminum, brass — in sheet, tube, wire |

📌 Best for tech accessories, watch displays, travel retail setups.

📦 4. Cardboard: For Lightweight, Low-Cost, and Short-Term Impact

| Attribute | Value |

|---|---|

| Finish | Laminated, die-cut, full-color print |

| Brand Look | Vibrant, temporary, promotional |

| Use Cases | Ship-flat kits, FMCG trials, events |

| Pros | Fast lead time, low cost, recyclable |

| Cons | Moisture sensitive, non-premium feel |

| Variants | 3-ply, duplex board, honeycomb |

📌 Best for pop-up launches, eco-brands, mass sampling.

🧩 5. Hybrid Materials: Where Design Meets Practicality

Many clients choose hybrid structures to balance look, load, and logistics.

| Combo Type | Why It Works |

|---|---|

| Acrylic top + MDF base | Visual clarity + structural support |

| Metal frame + cardboard skin | Rigid core + cost-effective print layer |

| Velvet insert + acrylic wall | Premium touch + product visibility |

| Wood veneer + steel structure | Texture warmth + long-term stability |

📌 Combine materials when you need to balance luxury image with budget — or create reuse potential.

🧾 Material Comparison Table

| Material | Cost | Visual Impact | Weight | Durability | Ideal Use Duration |

|---|---|---|---|---|---|

| Acrylic | $$$ | ★★★★★ | Medium | Moderate | Long-term premium |

| MDF | $$ | ★★★★☆ | Heavy | Strong | Mid-to-long term |

| Metal | $$$$ | ★★★★★ | Heavy | Excellent | Permanent fixture |

| Cardboard | $ | ★★☆☆☆ | Light | Low | Short-term |

🧩 Case Example: Skincare Brand Hybrid Display Rollout

A premium skincare client in Korea needed:

- A tester tray system with elegant branding

- Designed for rollout across 80+ retail counters

- Must be cost-efficient but feel luxury

Samtop’s solution:

- Acrylic tester cover for clarity and brand logo

- PU-coated MDF base for structure and matte finish

- Velvet pad insert for soft premium feel

- Flat-pack design for air shipping

💡 Result: 21% uplift in tester trial rates + easy reassembly by store staff in under 10 minutes.

💬 Frequently Asked Questions

Q: What’s the best material for high-traffic airport retail?

✅ Avoid cardboard. Use sealed MDF + acrylic or metal frames for wear resistance and humidity control.

Q: Can cardboard displays look high-end?

✅ Yes — with UV printing, lamination, and smart structural shapes, especially for eco-positioned brands.

Q: Are hybrid material displays harder to ship?

✅ Not if designed well. Flat-pack, KD structures with nested materials can reduce CBM and shipping cost.

🎯 Conclusion: The Right Material is a Design Decision — and a Business One

✔️ Acrylic = sharp visuals for product-led campaigns

✔️ MDF = versatile core for structure and mass use

✔️ Metal = long-life strength and luxury hardware feel

✔️ Cardboard = quick, eco, and promotional

Choose materials by store conditions, rollout plan, and brand tone. Combine when needed.

At Samtop, we test, prototype, and combine substrates to support brand storytelling — while respecting logistics and unit economics.

📩 Need Help Choosing Materials for Your Next POP Display?

We offer:

🧾 Material swatch packs & finish samples

💡 Substrate pairings by brand aesthetic

📦 Packaging optimization for air/sea freight

🔧 Hybrid display structure engineering

- Internal Links:

/contact– for inquiry/portfolio– materials in action/blog/pop-vs-pos-display-differences- External Links:

- Retail Materials Standards – Shop!

- Acrylic Display Properties – Perspex