Why the Right Integrator Outperforms a Factory-Only Model in Visual Display Projects

By Yan Luo | Samtop Display

Table of Contents

Many brands assume working directly with a factory is cheaper and faster — but for complex, brand-sensitive displays, it often creates more risk. A professional integrator offers cross-material coordination, visual QC, and brand-aligned execution that most single factories can’t deliver.

“Aren’t trading companies just middlemen?”

“Why pay more if a factory can make it directly?”

“How do I know if a partner adds real value?”

Let’s break down when integration wins — and when factory-direct may fall short.

For POP and VM display projects, going factory-direct often means managing 3–5 vendors, mismatched timelines, and siloed specs.

You face delays, broken communication, brand inconsistency, and costly last-minute fixes — especially with global rollouts.

The right integrator reduces risk, consolidates complexity, and protects your brand from design to delivery.

🧠 What Factories Do Well — And Where They Struggle

| Factory Strengths | Common Gaps |

|---|---|

| CNC cutting, spraying, high-volume runs | Can’t manage acrylic + LED + wood together |

| Efficient on unit cost | Poor understanding of brand or packaging logic |

| Deep material expertise | Struggles with VM nuance and store logic |

| Good at replicating samples | Poor at handling rush updates, global drops |

| In-house control of one process | No visibility into other vendors or global schedules |

📌 Factories are great at building parts — not at making retail-ready displays.

🧩 What a Trading Integrator Adds (When Done Right)

At Samtop, we integrate, not just source. That means we align engineering, production, quality, and logistics into one managed flow.

| Capability | How It Helps |

|---|---|

| Cross-material coordination | Prevents gaps across factories (e.g., acrylic, wood, LED) |

| CAD + spec translation | Ensures design intent is preserved through production |

| Unified production timeline | Avoids delivery delays and mismatched schedules |

| Visual QC at all sites | Catches errors early, ensures consistency |

| VM display logic | Optimizes setup, labeling, and store workflow |

| Packaging + customs + drop-shipping | Preps units for global rollout, not just factory exit |

🧠 We act as your display execution partner — not just a quote broker.

🔍 Real Example: Multi-Factory, One Campaign

Project: Global launch of a skincare pop-up display in 12 cities, 3 formats

| Component | Factory | Problem Without Integration |

|---|---|---|

| Acrylic tester trays | Factory A | Out of sync with graphics |

| Fabric lightboxes | Factory B | Logo misaligned |

| Wooden base units | Factory C | Wrong finish tone |

| Printed graphics | Factory D | Delivered late, no final QC |

With Samtop integration:

- Unified material board shared across vendors

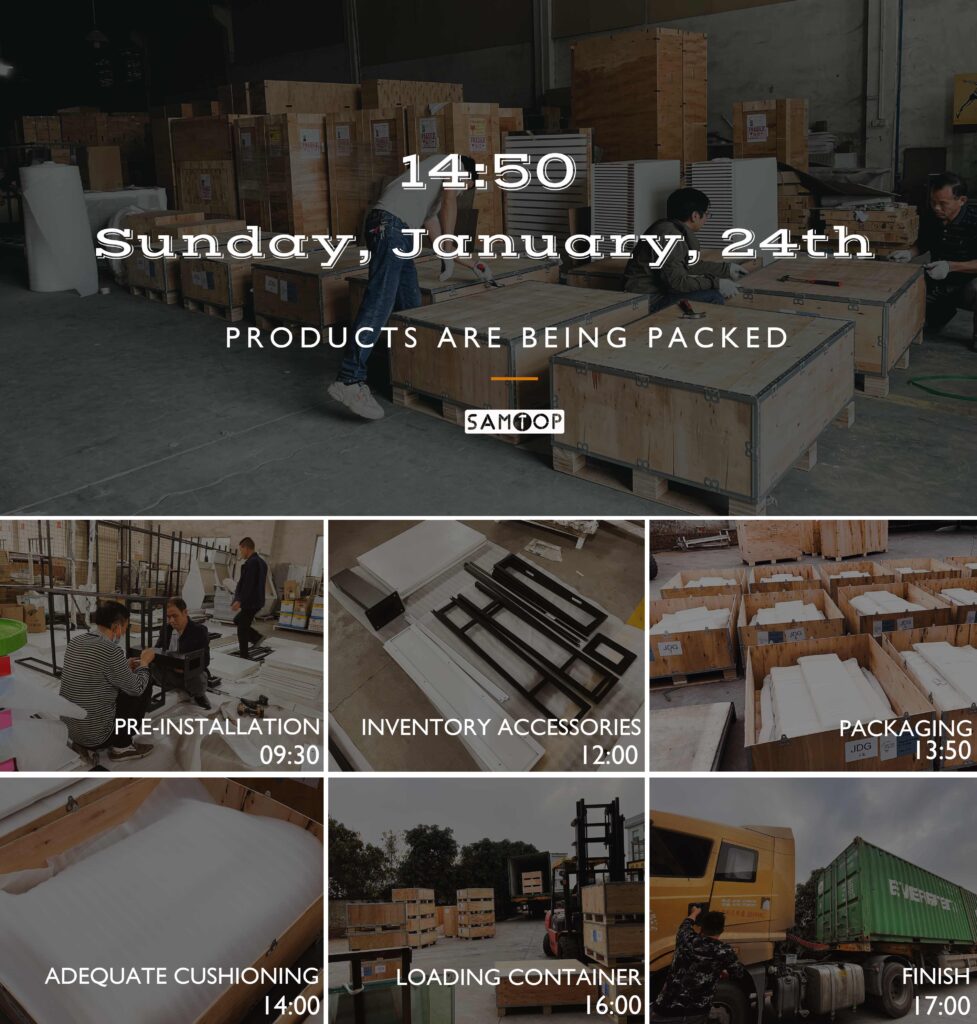

- Pre-shipment photo QC at a central site

- Shared packaging checklist → smooth install at each city

- One point of contact — not 4 threads and missed messages

✅ Delivered on time, 100% aligned visually

✅ Saved the brand from rework and last-minute freight

⚠️ Risks of Going Factory-Only (Direct, But Incomplete)

| Risk | Consequence |

|---|---|

| No packaging foresight | Breakage in transit |

| Siloed communication | Mismatched logos, wrong SKUs |

| No color or brand alignment | Finish tone inconsistency |

| Uncoordinated deliveries | Late arrivals, store complaints |

| No escalation buffer | One issue = full timeline delay |

💬 A display is only as strong as its weakest vendor.

Managing 4 factories = carrying 4x the risk and 0x accountability.

💬 Frequently Asked Questions (FAQ)

Q: Does a trading partner always mean higher cost?

A: No — a good integrator reduces cost in logistics, repacking, rework, and missed deadlines, often resulting in a better net ROI.

Q: How can I tell if a partner adds value (vs. just reselling)?

A: Ask if they provide:

- Engineering file translation

- Consolidation of materials

- Visual QC

- Pre-shipment packaging setup

- Region-specific drop-shipping

If the answer is “no,” you’re likely dealing with a broker — not an integrator.

Q: Can I get transparent breakdowns from integrators?

A: Yes. At Samtop, we can provide:

- Per-factory line item quotes

- Bundled execution pricing

- Cost-saving comparisons (e.g., separate vs. integrated logistics)

📩 Need an Integrator for Your Multi-Factory Display Project?

At Samtop, we provide:

- Full-scope project coordination

- Technical translation of brand visuals into engineering files

- Material + supplier integration

- Pre-shipment QC + packaging prep

- Global drop shipping and documentation

📧 Email: [email protected]

🌍 Visit: www.samtop.com