Retail display sourcing sounds simple — until your fixtures arrive scratched, oversized, or too late. If you’re managing your first global rollout, the most dangerous risks aren’t in manufacturing — they’re in briefing, coordination, and assumptions.

Table of Contents

✅ The good news? With better systems and supplier collaboration, you can avoid delays, budget blowouts, and brand embarrassment.

At Samtop Display, we’ve helped 100+ brands launch across 30+ markets. This guide highlights the top 6 mistakes first-time procurement leads make — and exactly how to avoid them.

✅ Summary for Rollout Managers

If you want your first global fixture program to land smoothly, avoid these:

- ❌ Quoting from a render, not a real brief

- ❌ Approving mismatched samples

- ❌ Forgetting packaging & CBM planning

- ❌ Skipping teardown or reuse logic

- ❌ Ignoring in-store physical limits

- ❌ Lacking a regional rollout playbook

Read on for practical fixes and file templates to protect your timeline and your team.

🚨 1. Quoting Without a Proper Spec Brief

What goes wrong:

- Supplier guesses materials or dimensions from renders

- Hidden costs appear in prototyping, LEDs, teardown design

- Timeline shifts when changes come too late

✅ Solution: Use a full RFQ package, not just moodboards. Include:

- 📏 Dimensions, weight load, KD requirement

- 🎨 Finish spec: Pantone, gloss %, texture

- 🔌 Power spec: 230V? UL plug?

- 🛠️ Logo material, size, and positioning

- 📦 Store install constraints (door, lift, setup staff)

📌 Grab our free fixture briefing template

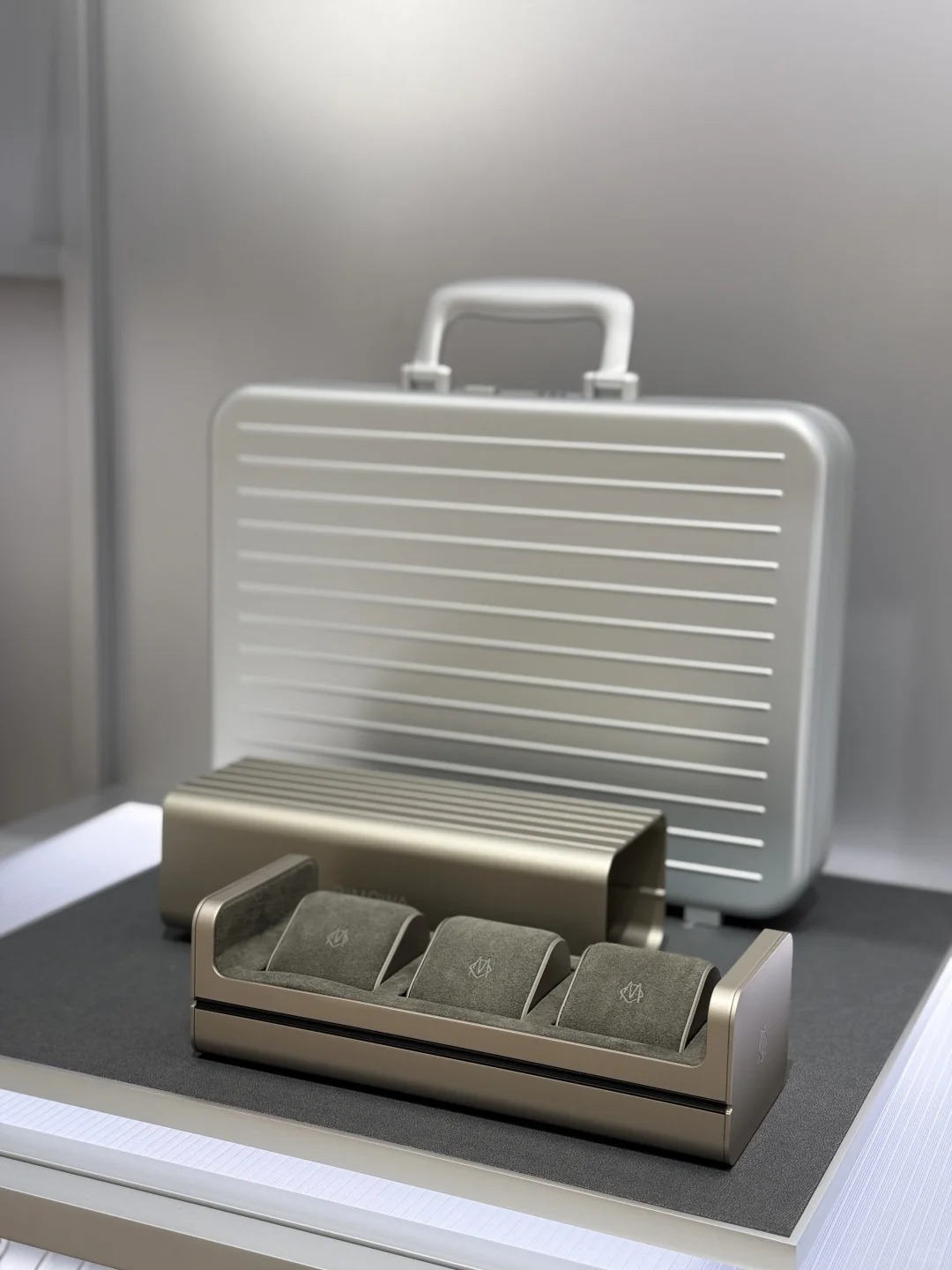

🎨 2. Approving a Sample That Doesn’t Match Final Production

What goes wrong:

- PPS color doesn’t match mass batch

- Logo position shifts

- Gloss feels off under 3000K lighting

- Brand visual looks inconsistent across stores

✅ Solution:

- Step 1: Material + color swatch

- Step 2: Full prototype sample

- Step 3: Final QC-approved branding under store light

- Request Pantone + ΔE values + batch photo every 100pcs

📌 Learn more about visual QA and finish matching

📦 3. Underestimating Packaging and Shipping Risk

What goes wrong:

- Fragile acrylic cracks in transit

- Overweight carton = air freight spike

- Unlabeled KD parts = in-store setup delays

✅ Solution:

- Co-design packaging with the fixture

- Add foam tray + labeled parts + QR setup sheet

- Include CBM, weight, and stacking rules

- Drop-test a fully packed unit before approval

📌 Read our full guide to shipping-friendly fixture design

🔄 4. Not Planning for Teardown or Reuse

What goes wrong:

- Fixture goes to landfill after one campaign

- Stores can’t disassemble safely

- No spare screws or repair plan

✅ Solution:

- Design modular displays with removable graphics

- Include teardown video via QR

- Add spare parts kit (feet, screws, logo plate)

- Store team gets pre-labeled storage box size

📌 Learn how we build reuse-ready fixture systems

🏬 5. Fixture Doesn’t Fit Real Store Conditions

What goes wrong:

- Too tall for store ceiling

- Plug doesn’t match voltage

- Localized graphics not ready

✅ Solution:

- Map store types (flagship, boutique, kiosk)

- Ask local trade team about plug, power, artwork

- Send 1 test kit per format

- Localize visuals before print

📌 Use our multi-country fixture checklist

🧩 6. No Rollout Playbook or Assembly Guide

What goes wrong:

- Store team improvises build

- QA team asks same questions 20×

- Regional partners don’t follow master plan

✅ Solution:

- 1-page rollout sheet with:

- Setup photo + step list

- Estimated time

- Contact person + QR code for help

- Labelled parts + tool list

- Use cloud folders per region

📌 Download our rollout folder template

💬 FAQ

Q: What’s the biggest hidden cost in a VM fixture program?

✅ Fixing broken displays from bad packaging — or air-freighting oversized units.

Q: How can I train installers across 20+ countries?

✅ Use QR-linked install videos with visuals + subtitles. Include in each crate.

Q: How do I ensure logo placement is always right?

✅ Use a CNC stencil plate + QC signoff photo for every 50–100 units.

✅ Conclusion: Fail Early or Prepare Smarter

✔️ A good brief avoids surprise quotes

✔️ Samples must match real store context

✔️ Packaging is part of the product

✔️ Teardown logic saves money & waste

✔️ Regional rollout = visual consistency

✔️ The 25th store deserves the same fixture quality as the 1st

At Samtop, we help brands prevent these mistakes through better briefing, smarter rollout structure, and quality-first engineering.

📩 Need Help Structuring Your First Rollout?

We offer:

- 📐 Spec + RFQ templates

- 🧾 Sample QA tools

- 📦 Packing diagrams + CBM calculators

- 🌍 Rollout folder structure + store team guides