In today’s society, metal products are ubiquitous. From daily necessities to high-end artworks, they all reflect the unique charm of metal. In the field of high-end metal sculptures, metal display stands, and luxury boutique store projects, metal surface treatment technology plays a significant role. Through various treatment methods, we can give metal products different visual effects and textures, and meet various design requirements and aesthetic needs. This article will detail various metal surface treatment technologies and their applications, hoping to provide useful references for your projects.

Table of Contents

1. Polishing

Polishing is a common metal surface treatment method that makes the metal surface smooth and bright with a high gloss effect through friction and abrasion. Polished metal products have strong visual appeal and are suitable for high-end product displays and decorations. Polishing is commonly used for stainless steel, aluminum, copper, and other metal materials.

2. Brushing

Brushing creates a delicate texture on the metal surface, producing a soft luster. Brushed metal surfaces have good scratch resistance and are suitable for furniture, display stands, and other applications. Brushing can be achieved through hand sanding or mechanical grinding.

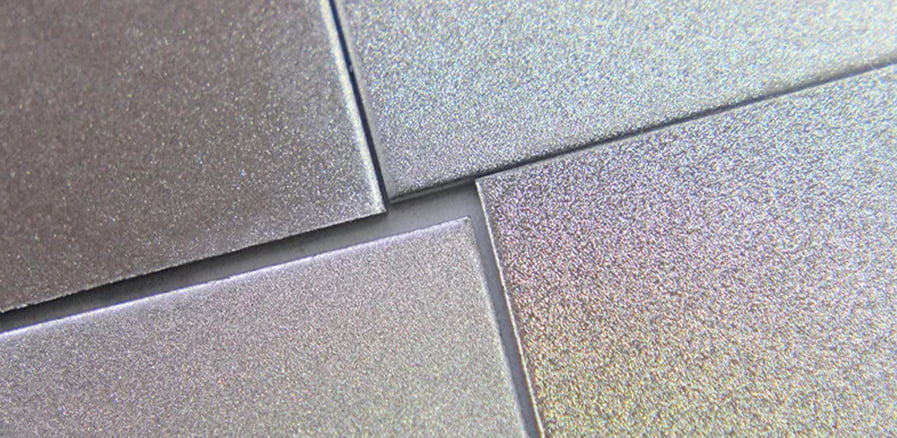

3. Sand blasting

Sandblasting is a method of using high-speed jetted sand particles to form uniform, delicate matte textures on metal surfaces. Sandblasted metal surfaces are both beautiful and wear-resistant and are suitable for multiple applications. Sandblasting often uses compressed air to spray sand particles onto metal surfaces and can be applied to materials such as stainless steel, aluminum, and copper.

4. Coating

Coating treatment is a technique that forms a thin protective or decorative film on the metal surface, such as gold plating, chrome plating, and zinc plating. The coating can improve the metal’s corrosion resistance, wear resistance, and aesthetics, and is suitable for high-end metal sculptures and luxury display stands. The coating can be achieved through electroplating, chemical plating, hot-dip plating, and other methods.

5. Anodizing

Anodizing is a method of forming a hard, wear-resistant oxide film on the metal surface. This treatment is commonly used for aluminum products, such as aluminum alloy display stands and sculptures. The anodized film has good corrosion resistance and aesthetics and offers a rich color selection to meet individual needs.

6. Electrophoretic Coating

The electrophoretic coating is a method of forming a uniform and tightly attached coating on the metal surface. The electrophoretic coating has high corrosion resistance and aesthetics and is suitable for various metal products. During the electrophoretic coating process, the object being coated serves as an electrode and is immersed in a water-soluble solution containing dissolved paint. The paint deposits on the metal surface through electrolysis.

7. Spray Coating

Spray coating is a method of applying various colors of paint onto a metal surface. Spray coating provides a rich color selection to meet individual needs. Spray-coated metal products are suitable for display stands, sculptures, and other fields. The spraying process can be done through air spraying, airless spraying, electrostatic spraying, and other methods.

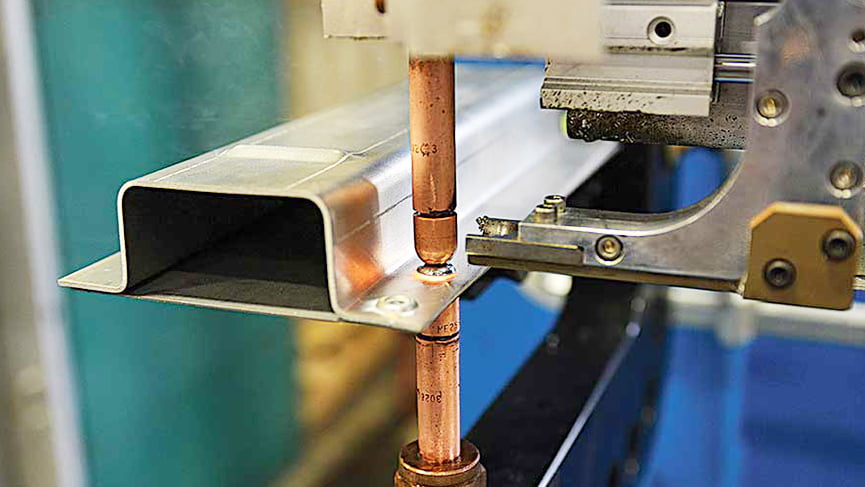

8. Welding

Seam Treatment For some metal structural parts, welding seam treatment is necessary to improve the product’s overall aesthetics and quality. Treatment methods include grinding, polishing, etc., making the weld seam smooth and reducing its appearance.

9. Etching

Etching is a technique of engraving patterns, texts, or textures on a metal surface. Etching can achieve exquisite decorative effects and enhance the unique art value of products. Etching can be achieved through acid etching, electrochemical etching, and other methods, and is suitable for various metal materials.

10. Riveting

Riveting is a method of connecting metal parts by fixing rivets. In some high-end metal products, riveting functions as both a connection and decoration. Riveting can be applied to metal sculptures, display stands, and other fields.

11. Hammering

Hammering creates uneven textures on the metal surface, producing an ancient and handcrafted feel. Hammered metal is suitable for retro-style sculptures, decorations, and other fields. Hammering is typically achieved through manual hammering or special hammering equipment to produce unique surface textures.

12. Pickling

Pickling removes rust, oil, and impurities from the metal surface, making it smooth and clean. Pickled metal products have good corrosion resistance and aesthetics. Pickling is often used for stainless steel, aluminum, copper, and other metal materials.

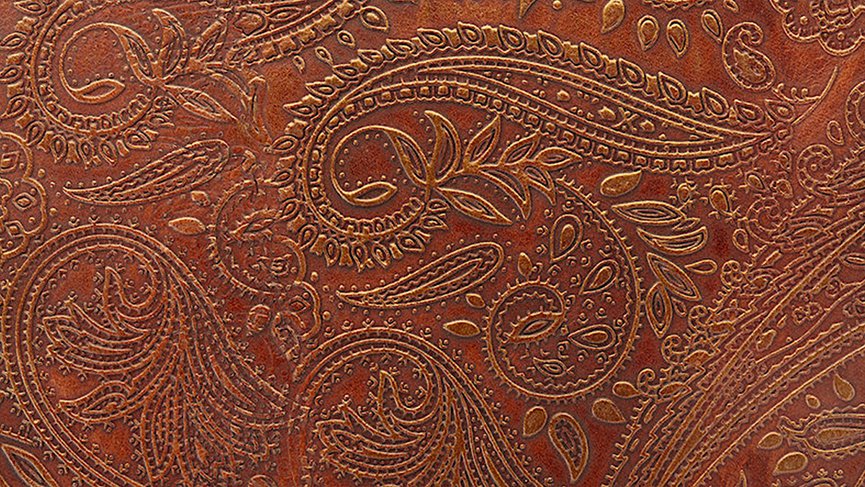

13. Engraving

Engraving is a technique of carving intricate patterns and textures on a metal surface. Engraved metal products have a unique art value and are suitable for high-end sculptures, decorations, and other fields. Engraving can be achieved through manual or mechanical carving methods.

Summary There are many types of metal surface treatment technologies that can be chosen based on the product’s requirements and design needs. These treatments not only improve the durability and corrosion resistance of metal products but also enhance their aesthetics and individuality. This article details various metal surface treatment technologies and their applications, hoping to provide useful references for your high-end metal sculptures, metal display stands, and luxury boutique store projects.

In the future, with the advancement of technology and innovative design concepts, metal surface treatment technology will continue to develop, presenting us with more novel and unique metal products. At the same time, environmental protection concepts will also play a significant role in metal surface treatment, promoting green and sustainable production methods.

Today, more and more designers and manufacturers are paying attention to the research and application of metal surface treatment technology. They are committed to exploring new technology methods to provide customers with higher quality and personalized metal products. We believe that in the near future, metal surface treatment technology will become more sophisticated, creating more possibilities for human life and engineering projects.

In your next project, try using these metal surface treatment technologies to add a unique charm to your metal sculptures, display stands, and luxury boutique store projects. Properly using these technologies will not only enhance the durability and aesthetics of your products but also showcase your brand image and temperament, providing more value and appeal to your projects.

In practical applications, it is recommended that you work with experienced metal surface treatment experts to ensure the correct implementation of technology and excellent results. They will provide professional advice and customized solutions based on your needs and project characteristics. At the same time, pay attention to industry trends, and learn about emerging technologies and trends to maintain a leading position in the competitive market.

As a content copywriting expert, I hope to provide you with a detailed introduction and application of metal surface treatment technology through this article, helping you better understand and master this field of knowledge.