When shopping, we often come across various sculptures both inside and outside malls or stores. Retailers strategically place them at storefronts, counters, and display windows. These sculptures range from cartoon characters to product props or intricately designed decorative pieces. Some are equipped with lights and even interactive features, capturing our attention and providing a unique shopping experience. But how are they made? This article will outline various methods for creating commercial sculptures, helping you choose the appropriate technique based on the sculpture’s purpose, placement, and size.

Table of Contents

Polystyrene Sculpture

Polystyrene is suitable for crafting simple sculptures. Typically, artisans use knives to carve the desired shape from a solid piece of polystyrene. They then apply glue to its surface, followed by painting or adding visual effects using stickers or other materials. Multiple rounds of sanding are often required during this process. These sculptures are only suitable for indoor use, as they tend to weather when exposed to the elements. However, polystyrene sculptures boast vibrant colors and are budget-friendly, making them ideal for holiday-themed displays in shopping malls.

Fiberglass Sculpture

Fiberglass sculptures are crafted using Fiberglass Reinforced Plastic (FRP). Artisans layer resin mixtures and fiberglass within pre-made molds, which are then polished and painted after the resin has cured. Fiberglass sculptures are known for their high strength and resistance to corrosion, making them suitable for both indoor and outdoor placement. For larger sculptures, separate components can be created and later assembled using special adhesives, welding, or mechanical connections.

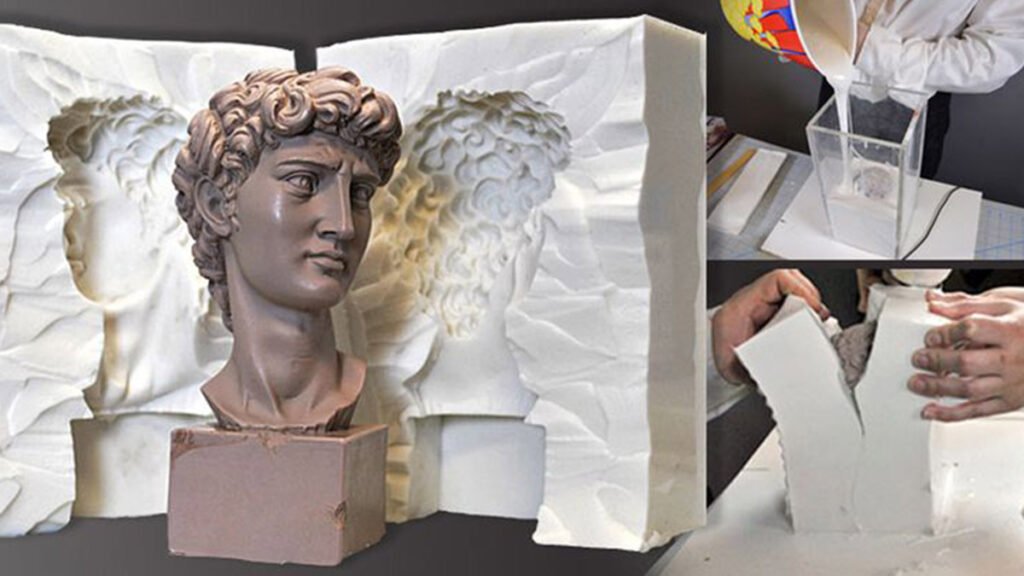

Mold-Making Sculpture

A commonly used method for crafting sculptures is vacuum casting. It involves creating a mold from a perfect sculptural prototype and pouring liquid material into this mold. Once solidified, the sculpture is removed from the mold and undergoes post-processing like sanding and painting. Silicone molds are typically used for vacuum casting and are ideal for creating sculptures with complex shapes or intricate details. However, products produced using mold-making techniques may experience some shrinkage.

3D Printing Sculpture

3D printing combines Computer-Aided Design (CAD) with 3D printing technology, allowing for precise, fast, and flexible sculpture production. The application of 3D printing has become widespread, and the process of printing sculptures is similar to printing other objects. After printing, post-processing steps such as support structure removal, surface cleaning, sanding, and finishing are required to achieve a smooth appearance. 3D printing can produce sculptures with complex structures and details, catering to individualized needs and creative expression. However, due to the layered printing process, visible layer lines may remain on the sculpture’s surface. It is primarily used for producing the first prototype or for low-volume production.

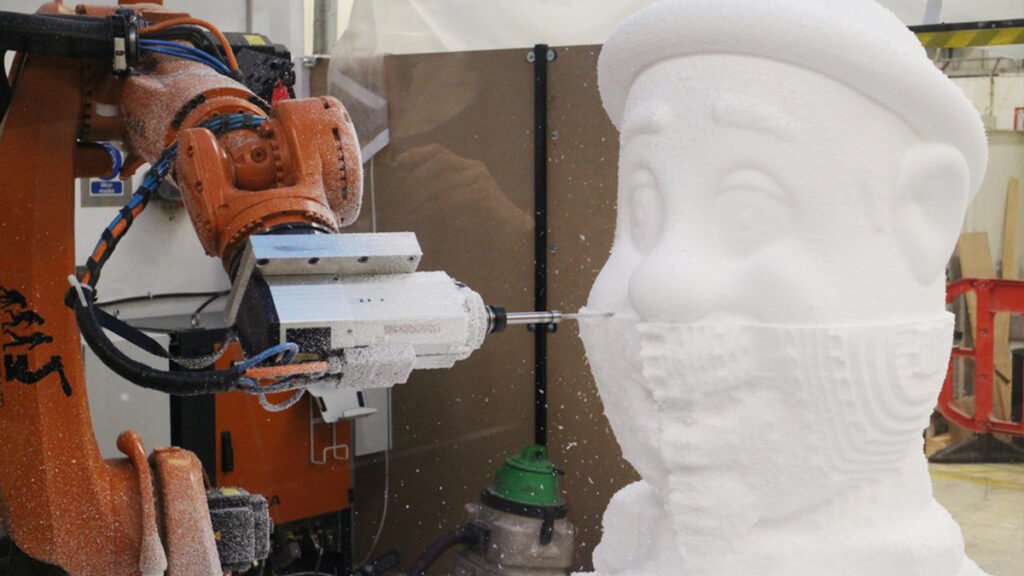

CNC Machining Sculpture

CNC machining is another viable method, requiring CAD drawings for precision, efficiency, and automation. Various materials, including wood, metal, stone, and foam board, can be sculpted using CNC machining. Sculptures produced through this method require surface treatments such as sanding and painting to enhance their artistic appeal. CNC machining allows for large-scale production or the creation of sculptures with intricate shapes while maintaining consistency and accuracy.

Hand-Crafted Sculpture

Hand-crafted sculptures are a traditional method of sculpture making, requiring artisans with advanced skills and artistic creativity. Common materials for hand-crafting include marble, wood, clay, gypsum, and metal. Different materials present varying levels of difficulty and require specific tools, for example, stainless steel sculptures require the use of cutting machines and welding tools. Hand-crafted sculptures can achieve uniqueness, intricacy, and dimensionality, but they are time-consuming, making mass production nearly impossible.

In designing store sculptures, considerations should include the store’s positioning, brand image, and the environmental characteristics of its location. They should harmonize with the overall store design and decor style, emphasizing the store’s uniqueness and personalization.