A Step-by-Step Playbook for Durable, Brand-Aligned Retail Displays

By Yan Luo | Samtop Display

Table of Contents

✅ Buying floor displays from China can be fast, scalable, and cost-effective — but only if you approach it with clear specs, supplier vetting, and rollout foresight. Many buyers stumble on vague RFQs, misaligned samples, or poor shipping structure.

At Samtop, we’ve helped global VM and procurement teams source and ship floor fixtures that look right, arrive safe, and last across campaigns. Here’s our sourcing blueprint.

✅ Summary: What to Get Right When Buying Floor Fixtures from China

To succeed with your fixture order, you must:

✔️ Define fixture type + brand finish expectations

✔️ Choose the right factory for your mix (wood / metal / acrylic)

✔️ Prepare complete technical specs, not just renders

✔️ Sample logically — material first, then structure

✔️ Plan for knock-down, CBM efficiency, and store rollout handling

📌 Related: How to Write a Factory-Ready Fixture Brief

🧩 1. Define Your Floor Fixture Type (And Match the Right Supplier)

| Fixture Type | Use Case | Notes |

|---|---|---|

| Plinth / Podium | Hero product, fragrance, jewelry | MDF or acrylic, often premium finish |

| FSDU | Promo or mass display | MDF + metal or corrugate, price-driven |

| Modular Shelving Tower | Multi-SKU rollouts | Precision assembly, requires 3D drawing |

| Backwall Bay / Counter Island | Shop-in-shop, beauty corners | Usually needs lighting + logo integration |

| Gondola / Mid-floor Unit | Store layout fixtures | Metal + wood laminate, 4-sided display |

📌 One supplier rarely does it all — find one who excels at your primary material (e.g. acrylic, powder-coated metal, MDF).

🧠 2. Supplier Vetting Questions That Matter

- “Do you fabricate all materials in-house or outsource some (metal, acrylic)?”

- “Do you provide 3D drawings + assembly diagrams for approval?”

- “Can you integrate LED + logo plaques into the structure?”

- “Do you offer flat-pack designs to save CBM?”

- “What’s your certification experience? FSC, UL, CE?”

📌 Related: How to Vet a Fixture Factory in China or Vietnam

📐 3. Cost-Efficiency Tips Without Compromising Quality

✔️ Use a shared base design across multiple SKUs

✔️ Avoid over-complex angles or shapes (adds tooling + paint defects)

✔️ Design for flat-pack (KD) to cut shipping volume

✔️ Combine SKUs with shared BOM parts

✔️ Lock pricing only after test production to validate real costs

📌 “Cheaper per piece” doesn’t matter if you’re paying extra per crate in freight.

⚙️ 4. What to Prepare for Quoting (RFQ Must-Haves)

- ✅ Dimensions + expected load

- ✅ Exploded drawings or CAD (PDF/DWG)

- ✅ Finish spec: Pantone, gloss %, texture type

- ✅ Branding spec: logo method, zone, material

- ✅ LED spec: voltage, cable exit, dimming (if any)

- ✅ Packing method: foam, KD, pallet spec

- ✅ Store-level install requirement (video/manual?)

📌 Related: What to Include in a Display BOM

🧪 5. Sampling + QA: Save Cost, Avoid Risk

| Step | Reason |

|---|---|

| Sample each material separately | Avoid full unit rework if only finish fails |

| Ask for assembly video | Flat packs often confuse store teams |

| Ship 1 full test kit internally | Touch, test, and stress before approval |

| Provide a QC checklist | Define acceptable gaps, gloss, color |

| Approve photos every 50–100 units | Prevent full-batch mismatch |

📌 Related: Visual QC Setup for VM Fixtures

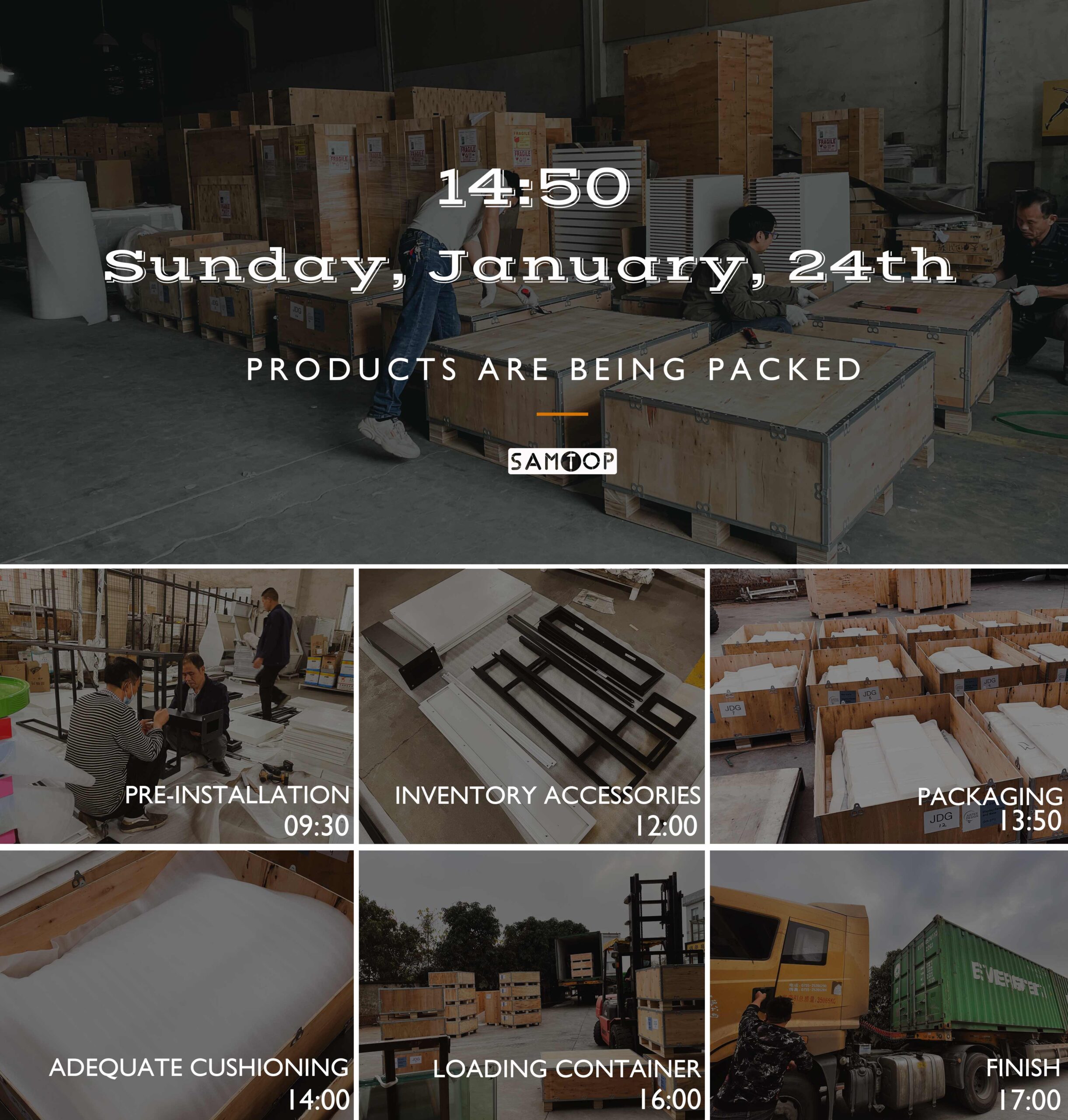

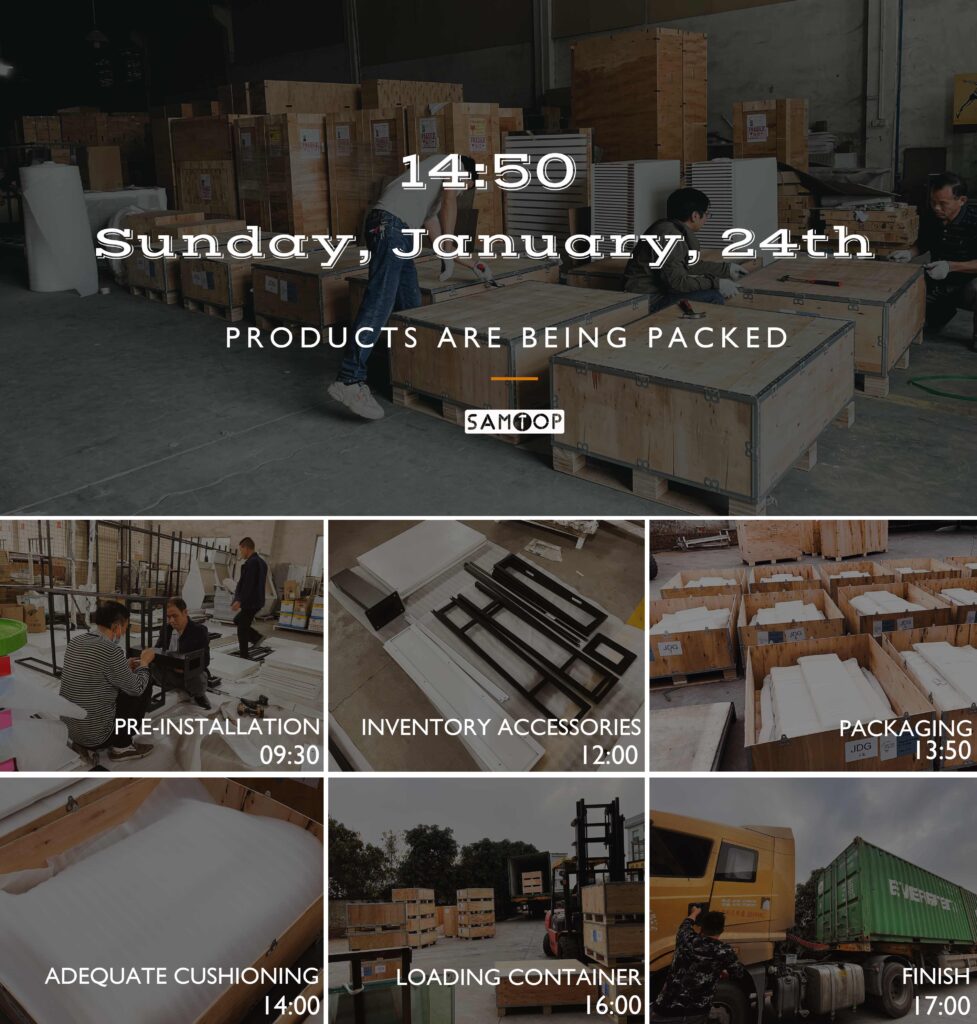

🌍 6. Logistics & Shipping from China

✔️ Use EPE foam + structured trays for fragile gloss surfaces

✔️ Match pallet sizes to warehouse spec (Euro/US)

✔️ Align on correct HS Code (9403 for MDF/metal, 3926 for acrylic)

✔️ Request: PI + COO + test report + packing list in advance

✔️ Bundle SKUs per rollout destination to reduce repack

📌 Add spare screws, glue, logo plates, and touch-up pens in every crate.

🧪 Advanced: How to Pre-Test Multi-Material Finishes

Each material = unique finish risk. Use one sample board for multiple checkpoints.

| Material | Risk | Prevention |

|---|---|---|

| MDF | Edge chipping, uneven paint | Ask for lacquer vs. water-based coating detail |

| Metal | Rust, uneven gloss | Request indoor vs outdoor grade powder |

| Acrylic | Scratches, glue marks | Use CNC cut + anti-fingerprint film |

📌 Related: How to Simulate Premium Finishes During Sampling

📦 Use BOM to Manage Cost + Rollout Accuracy

Your BOM should be the central spec file for vendor, logistics, QA, and install. Include:

- Part name + quantity + color + finish

- Material spec (e.g. FSC MDF, 304 stainless)

- Branding area method + alignment spec (±1mm)

- Join type (cam lock, dowel, bolt)

- Packing method (EPE, tray, zip bag, KD box)

- Version/date control

📌 Version control your BOM + use QR label if managing 3+ regions.

🧩 Prepare for Real-World Store Issues

| Issue | Solution |

|---|---|

| Missing parts | BOM print + color-coded tags per bag |

| Setup confusion | QR code video, no-text icons |

| Wrong plug/cable | Country-level power spec, not “EU” |

| Logo misplacement | Laser template + adhesive guides |

| Store fix needed | Include hardware + extra logos + touch-up pen |

📌 Related: How to Coordinate Global Fixture Rollout Logistics

💬 FAQ

Q: How long from RFQ to store floor?

✅ Sampling: 10–15 days | Production: 30–45 days | Shipping: 3–6 weeks

Q: Can I get FSC or UL-certified materials?

✅ Yes. FSC MDF, CE plugs, and UL LED drivers are common in East China.

Q: Minimum Order Quantity?

✅ Many suppliers offer MOQ 30–50 sets. Price tiers improve >100 pcs.

Q: Is powder coat better than paint?

✅ Yes — powder is more scratch-resistant and preferred for retail touch zones.

✅ Conclusion: Smart Sourcing = Less Cost, More Confidence

✔️ Choose your factory by capability, not catalog

✔️ Define every detail in your RFQ + BOM

✔️ Sample smarter: 1 board = 10 answers

✔️ Use photo + video-based QC to scale without risk

✔️ Ship crate-ready with install instructions for every store

At Samtop, we help brand teams transform concepts into rollout-ready, in-store fixtures — combining engineering clarity, visual control, and manufacturing agility.

📩 Want Help Sourcing Your Next Floor Fixture from China?

We provide:

✅ 3D CAD + BOM development

✅ Factory vetting + production supervision

✅ Sample validation + visual QA logs

✅ Packing design + shipping setup

✅ Installation manual + rollout documentation

📧 Email: [email protected]

🌍 Website: www.samtop.com