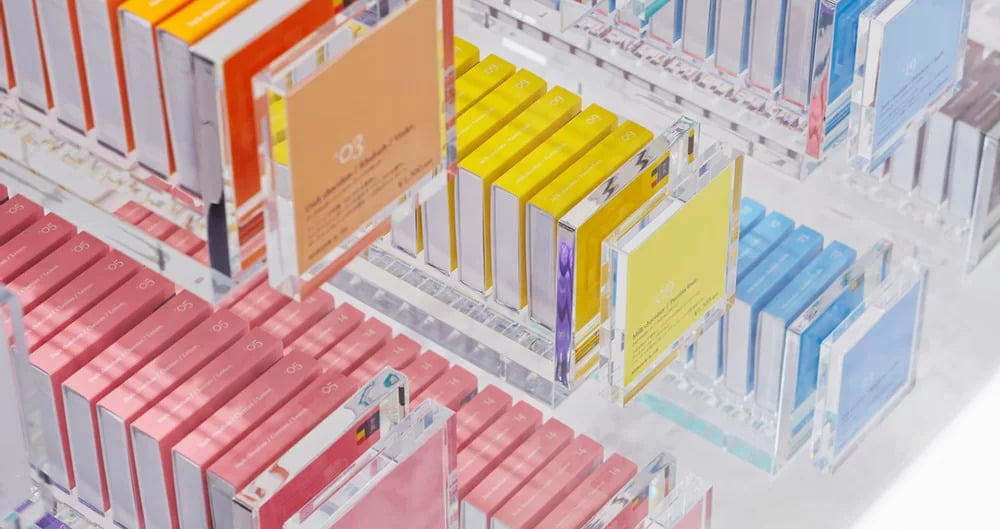

Acrylic is an early developed thermoplastic material with a wide variety of specifications, you can find almost any thickness and color you want, and you can even find acrylic sheets with the special effects you want. In the advertising industry, the use of acrylic products reached more than 80%, jewelry display, watch display, wine display, cigarette displays, electronic products display, and cosmetics display a lot of use acrylic sheet

Table of Contents

Advantages of acrylic when used as a display

High transparency

Transparent acrylic light transmission of more than 93%, visually gives a sense of purity. The penetration and reflection of light attract the attention of potential customers, while it does not take away the brilliance of the displayed products.

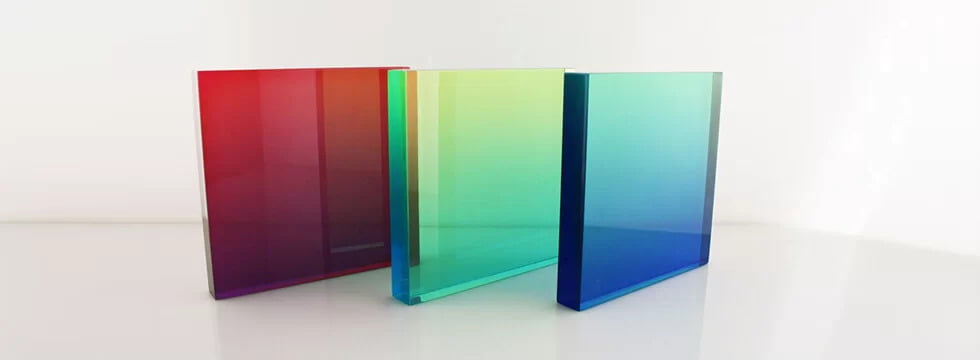

Easy to dye, easy to print

Acrylic itself has a variety of colors on the sheet, while in the dyeing process its surface coloring power is strong. In the production process, silk screen printing or UV printing on the acrylic surface effect is satisfactory, in the acrylic surface paste color painting (advertising) is also often used.

Weather resistance

Acrylic performance is stable and highly adaptable to the natural environment, even if a long time in the outdoor sunlight will not change the performance and color, good resistance to aging. Acrylic display can be used for a long time and is an affordable retail display solution.

Easy to clean and polish

In general, it is sufficient to dust the acrylic with a soft cloth. If necessary, use a soft cloth with warm water and mild detergent to wipe the acrylic, not use abrasive cleaners and chemical detergents containing amino acids. If the acrylic display has scratches on the surface during use, there are also acrylic polishing solutions on the market to make the acrylic display shiny and new.

Lightweight, easy to transport

The acrylic density of 1.18kg/dm³, the same volume size of the material, acrylic weight is only half of the ordinary glass, light metal aluminum 43%. The acrylic display is easy to handle and transport.

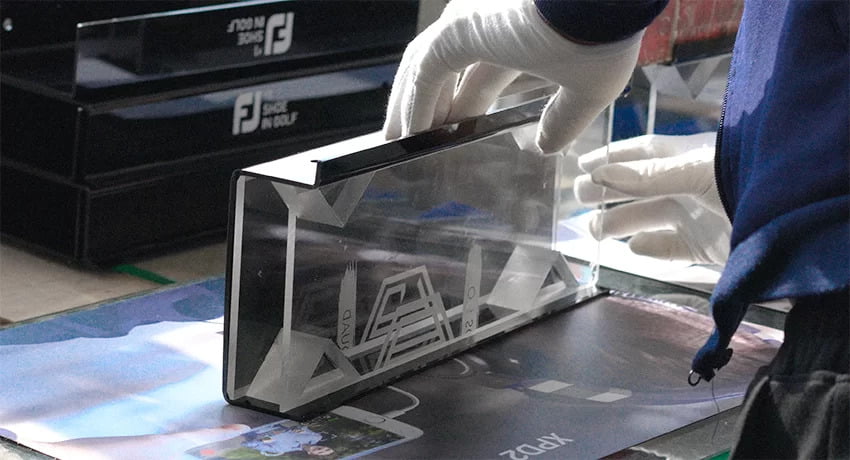

Strong mechanical height, easy to process

Acrylic belongs to the long chain of polymer compounds, and the molecular chain formed is very soft. Acrylic has high strength and is 7-18 times higher than glass in terms of tensile and impact resistance. It can not only use the lathe for cutting, and drilling, with adhesive glued into various shapes but also can be processed with plastic molding methods such as blistering, and thermoforming extrusion.

Acrylic display production and use precautions

The bonding place may turn white

After using the bonding agent should let the bonding agent dry naturally, using a fan to speed up the drying will make the acrylic bonding place white. Use the right amount of adhesive, too much adhesive will overflow and form tear marks on the acrylic, and less is not strong bonding.

Easy to burst the edge

Change the cutting tool for cutting acrylic on time to prevent the acrylic from bursting the edge. When pressing small accessories into the holes in the acrylic, it is necessary to design the size of the holes to avoid accessories squeezing out the acrylic plate.

Low melting point

The melting point of acrylic is 446°F-500°F, but the processing of up to 205°F can be hot bending. High-temperature things cannot be placed on the acrylic, when the acrylic is placed for a long time at 140°F to 203°F will be a slight deformation. Acrylic edges can be flame polished. In the process of laser cutting thick acrylic material to prevent excessive temperature can be sprinkled with water on the acrylic plate.

Soluble in organic solvents

Acrylic is a polymer compound, that will dissolve in organic solvents. In daily use as a display of goods maintenance, should be away from organic solvents, such as the alcohol composition of the cleaning agent. Acrylic cannot be swabbed with alcohol, after being swabbed with alcohol acrylic will appear with ice cracks.

Relatively low hardness, the surface is easy to leave scratches

The average Rockwell hardness value of about 90, compared to metal or glass is low. When cleaning the acrylic display avoid using a hard dry towel to wipe the acrylic surface directly to avoid leaving scratches. In the handling process to avoid dropping, acrylic bonding at the degree of force is weak.

Which part of the display is acrylic used for?

Acrylic Iluminada advertising letters

Because acrylic is easy to process due to good light transmission, LDE luminous three-dimensional letters are generally made of acrylic.

Acrylic organizer/case/tray/riser

It is a customized storage solution for your products to give them a neat and tidy appearance. Acrylic countertop displays.

Acrylic countertop displays

A countertop display is a small marketing tool placed on a countertop to attract impulse purchases.

Spherical or square acrylic cover

Whether it’s a trophy or a beautiful holiday Christmas ball, you need an acrylic cover to protect them.

Acrylic surface finishes or Backboard

Acrylic has a low weight capacity and cannot be used for large displays but can be used on the surface of a cabinet or as a backboard.

With its excellent performance in various industries, acrylic is also a common material in the advertising retail display industry, and we supply custom acrylic displays for various retail environments.