I would like to ask you something, do you know what printing processes are mainly used in the display industry? With this question in mind, we have decided to write an article to clarify them, I hope you like it! In retail design, the brand story, philosophy, promotional information, poster advertising, and product introduction of the store all need to be conveyed to customers through carriers, and different printing techniques are used on different carriers. If you are interested in the retail display industry, you can subscribe to us. We will always update interesting things happening in the industry and more knowledge in production.

Table of Contents

1. Digital printing

Digital printing includes inkjet and laser printing. It outputs the image directly from the computer to the printer, and precise inkjet with high-speed nozzles sprays ink to the surface of various substrates (rather than penetrating into the substrate). Substrates include paper, photo paper, canvas, glass, metal, marble, and other materials.

The digital printing process has low cost and can print high-quality images in a short time. It is commonly used in the production of display products such as posters, display boards, and signs. Digital printing patterns can also be mounted on the surface of display shelves.

UV printing is the most commonly used in the retail display:

UV printing is a new type of inkjet printing process that uses UV light-cured ink. There are no restrictions on the printed substrate, and the printed pattern is realistic and layered. When we need to make patterns on acrylic, glass, leather, or metal film, we often use this process.

We have tried UV printing on film, and the ink of the pattern will be mottled and fall off. After multiple adjustments, we found that the ink and pre-coating layer were not suitable. After the ink is solidified, the hardness can be divided into soft ink and hard ink. Different inks should be selected according to the substrate. Before UV printing on different substrates, corresponding coatings should be pre-coated to ensure that the ink can firmly adhere to the substrate.

2. Silk screen printing

The silk screen printing process is a semi-automatic printing process. The pattern is made into a film and then a screen is exposed, and finally, the ink is layered on the surface of the material with a flat surface through screen printing. It is used to make simple and less colorful patterns. The silk screen printing process has the advantages of high printing quality and strong durability. It is commonly used in the production of display products such as logos, and props.

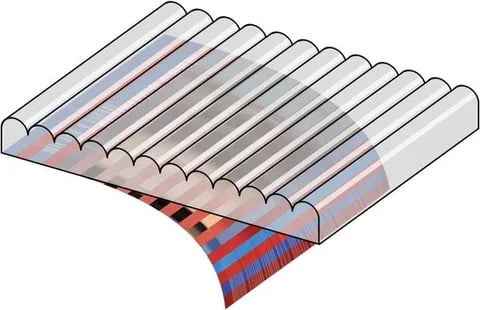

3. 3d lenticular printing

Grating stereo painting is a product of the combination of digital technology and traditional printing output technology, which uses special optical materials (commonly known as grating materials) to show a lifelike three-dimensional world on a flat surface. The grating painting allows a static picture to display different content at different angles, and can even achieve the effect of moving and confusing vision. Beverages, sports brands, or electronic products like to use this process to make cards and promotional advertisements.

4. Heat transfer printing

Heat transfer printing is a process that transfers images to materials by heating special printing paper. The substrate includes fabrics, plastics (plates, sheets, films), ceramics, and metal-coated panels. Heat transfer printing has the advantages of high image quality and bright colors. It is commonly used in the production of display products such as T-shirts, canvas bags, and counter mats.

5. Hot stamping

Hot stamping is a process that uses the principle of hot pressing and transfers the aluminum layer in the electro-aluminum to the surface of the substrate to form a special metal effect. Since the main material used for hot stamping is electro-aluminum foil, it is also called electro-aluminum hot stamping. Leather and fabric are suitable substrates for hot stamping. When we make display shelves for watches and jewelry, we often use this method to leave a luxurious logo.

The above are the most commonly used printing techniques in the retail design industry. If there are any supplements, if you want to learn more about the industry information, or if you have a retail display project that needs to be carried out, please feel free to contact us.