Where Good Ideas Go Wrong — and How to Build a Smoother Brand–Supplier Pipeline

By Yan Luo | Samtop Display

Table of Contents

Most display projects don’t fail because of bad design or poor production — they fail because of misalignment. From creative vision to material execution, even one communication gap can ripple into missed deadlines, mismatched finishes, and costly rework.

“The render looked perfect — the sample didn’t.”

“Why is the logo 3mm off?”

“It fit in CAD but not in-store.”

This article breaks down the 5 most common disconnects — and how to fix them before they become expensive.

🧠 1. Concept ≠ Engineering ≠ Manufacturing

The brand sends a sketch or 3D render. The factory produces from a flat file. And somewhere in between:

- Materials change due to cost or local stock

- Logo placement gets lost in translation

- Structural logic isn’t validated (balance, joinery, load)

- Scale doesn’t match real product or tester bottle

🎯 Fix:

- ✅ Require 2D + 3D engineering from supplier

- ✅ Confirm logo zones + unboxing plan

- ✅ Approve color + material swatches, not just render images

Most problems show up at the prototype stage — if there is one:

- No lighting mock-up? LED color is too blue

- No fit test with real product? Bottles don’t align

- No packaging trial? Corners arrive dented

🎯 Fix:

- ✅ Build sampling into your project calendar

- ✅ Ask for staged samples: material → structure → full visual

- ✅ Approve via photo/video + courier, not photo only

🔁 3. Too Many Stakeholders, No Central Gatekeeper

Typical roles:

- Brand team cares about visual polish

- Procurement cares about unit cost + MOQ

- VM team cares about rollout feasibility

- Supplier needs one clear decision source

But if everyone gives separate feedback — the supplier gets stuck.

🎯 Fix:

- ✅ Assign a project lead on the brand side

- ✅ Use a shared comment tracker or approval checklist

- ✅ Communicate feedback as one, not in silos

📐 4. Brand Standards Are Shared Too Late

Most factories don’t know:

- Pantone hierarchy

- Which parts must be matte vs. gloss

- Font files for laser etching

- Safety spacing or electrical code for malls

🎯 Fix:

- ✅ Share a “brand display guideline” at quoting stage

- ✅ Include logo in vector + PMS + packaging guide

- ✅ Treat the factory like a design translator, not just a builder

📉 5. Timelines Don’t Include Realistic Buffers

“We need this in-store in 4 weeks” sounds efficient, but:

- Sampling takes 2 weeks

- Shipping takes 2 weeks

- There’s no time for revision, QC, or repack

🎯 Fix:

- ✅ Reverse-plan from in-store date

- ✅ Pad in 1–2 weeks for approvals + logistics

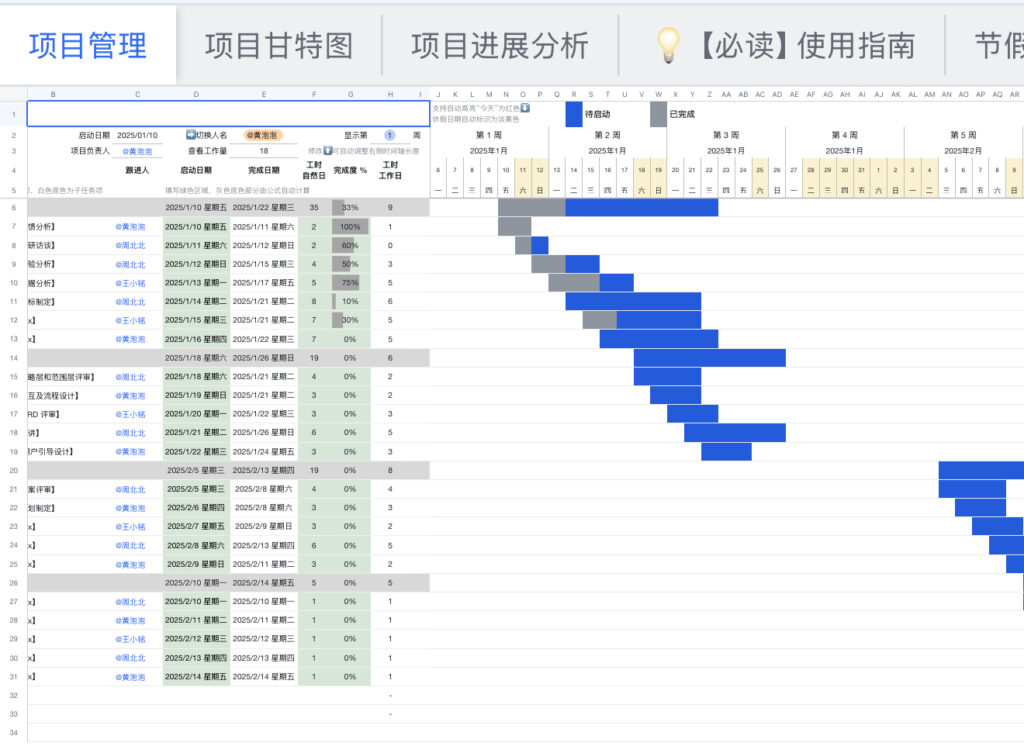

- ✅ Ask supplier for a Gantt chart or milestone view

🧩 Real-World Misalignment Example

Project: Premium light-up window display

What went wrong:

- Creative used RGB lighting in Keynote

- Factory chose cool white LEDs

- No sample sent

- Installed unit looked sterile and off-brand

Result: Reinstalled locally at 3x the cost

✅ Could have been avoided with:

- A lighting mock-up

- Color + material sample approval

💬 FAQ

Q: Whose responsibility is alignment — brand or supplier?

A: Both. The brand must explain visual goals clearly. The supplier must ask the right questions and confirm with proof.

Q: What if my supplier can’t produce engineering drawings?

A: Find a partner who can — interpretation is part of execution.

Q: Can Samtop help align across teams?

A: Yes — we coordinate with creative, VM, and logistics to reduce cross-team friction.

📩 Want to Prevent Misalignment in Your Next Rollout?

At Samtop, we:

- Translate 3D renders into production-safe technical drawings

- Build layered samples (material + structure + final finish)

- Offer shared checklists and milestone tools for brands and factories

- Consolidate stakeholder feedback into one execution source

📧 Email: [email protected]

🌍 Visit: www.samtop.com