Wood has always been the most common material used in retail environments today, whether it is for store decoration or for displaying merchandise on shelves, because it is readily available and inexpensive with many different derivative material categories, and the manufacturing supply chain has become very sophisticated.

Table of Contents

Wooden panels are often used in gondolas, wall shelves, counters, and other large permanent retail installations. They are environmentally friendly materials that do not age easily, are structurally strong, and can be disposed of in nature when abandoned. Sometimes wood materials are combined with metal to create sturdy displays with strong frames.

What are the common wooden materials used for retail displays?

Medium Density Fiber (MDF)

MDF is a type of lumber that is made by breaking wood into fiber-like chips and then gluing it together.

Advantages are cartable, easy to shape, affordable, environmentally friendly, and a smooth surface suitable for baking paint carving.

MDF is the most used material for display production, with a wide range of panel specifications, and is easy to polish. But easy to moisture, not load-bearing, easy to deformation, poor nail retention, so it needs to be stored or placed in a dry environment, while in the processing process to do a good job of primer treatment.

Melamine-Faced Chipboard (MFC)

Melamine Faced Chipboard is chipboard made by breaking the wood into fiber-like pieces and then gluing them together; the two sides of the core material are usually covered with Melamine.

The advantages of MFC are moisture resistance, pressure resistance, impact resistance, low formaldehyde, affordable price, environmental friendliness, good resistance to change the strength, and various surface embossing treatments. However, it is difficult to be processed into special irregular shapes, and MFC is recommended for overall custom store furniture with a limited budget.

Veneer core plywood

Plywood is made by stacking several layers of thin wood pieces, usually an odd number of veneers combined into one plywood, each veneer fiber direction intersects vertically, and the top and bottom veneer is the same wood direction.

The advantages are moisture resistance, good bending strength, and excellent load-bearing capacity. It is very suitable for large display cabinets that need to be load-bearing, but the price is higher than MFC and MDF.

Oriented Strand Board (OSB)

OSB is made by chopping the wood, stacking the wood chips, and then pressing them at high temperatures. The wood chips are stacked horizontally and vertically to effectively strengthen the density of the board and to create a special texture.

The advantages are environmentally friendly building materials, economical, good structural density, and not easily deformed & broken.

The disadvantages are heavyweight, lack of moisture resistance, and monotonous decoration. Sometimes it is used according to customers’ design requirements, but usually, it is used less often.

Solid wood

A solid wood panel is a wood panel made from whole wood (logs). Solid wood panels are generally classified according to the name of the panel substance (raw wood material), and there is no uniform standard specification.

The price is high but strong and durable, natural grain, mostly with the unique aroma of natural wood, with good moisture absorption and breathability, brands that advocate nature will use solid wood to produce retail displays.

Bamboo (also attached)

A panel made from a piece of processed bamboo sheets that are glued and pressed has the same natural grain as solid wood, but the grain is monotonous. Bamboo panels are prone to bursting edges in the process of making displays, and the surface needs to be polished several times to form a delicate and smooth effect. Bamboo retail displays (usually small) need to be placed in dry spaces, it is susceptible to moisture and mold, but it is an affordable retail display solution that demonstrates an environmentally friendly concept.

What are the common processes for wood displays?

Cutting

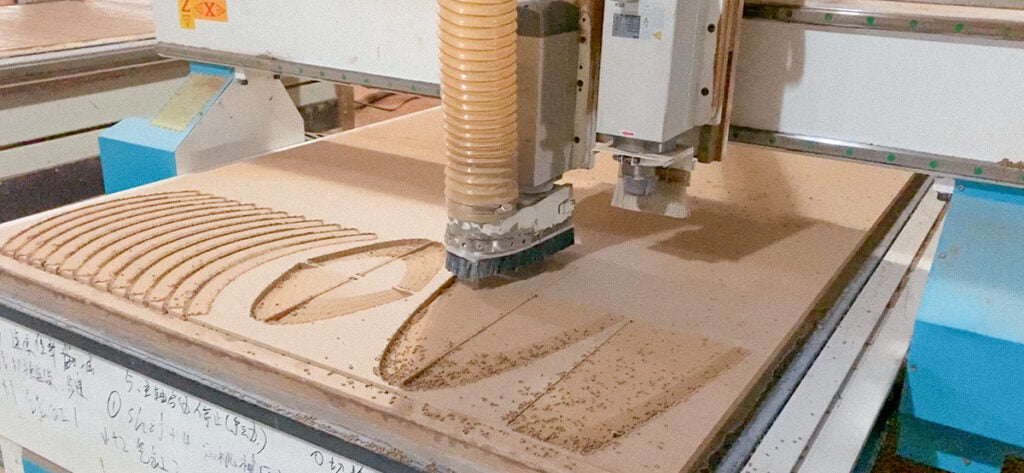

Change tools on time to prevent the cutting surface from bursting due to cutting. Straight cutting with a table saw if it is shaped cutting available to CNC or laser (it is worth noting that the laser will make the wood fiber scorched and blackened)

Trimming and grooving the edges

Cut the edges to the desired angle for bonding.

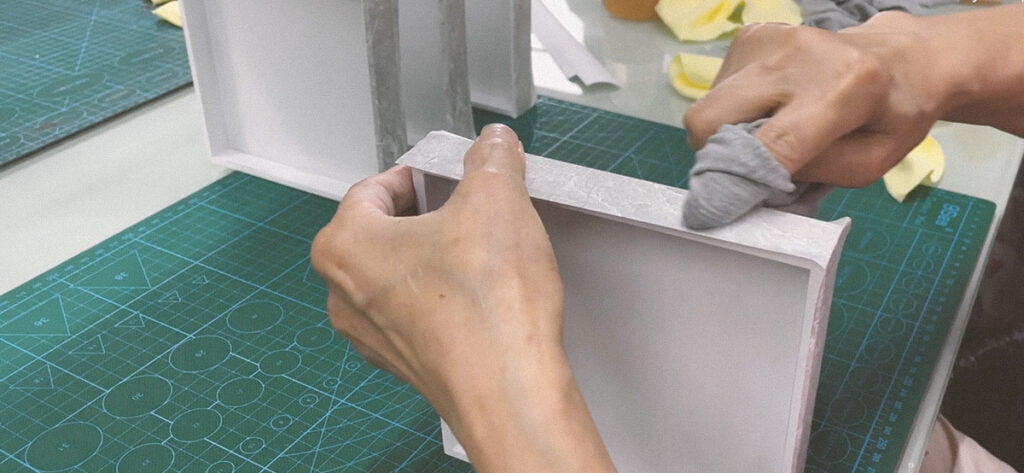

Sanding

Before painting, you need to sand the panel flat, if there is a slight dent, you can make up the poly-putty base and then sand to ensure that the paint surface is flat after painting.

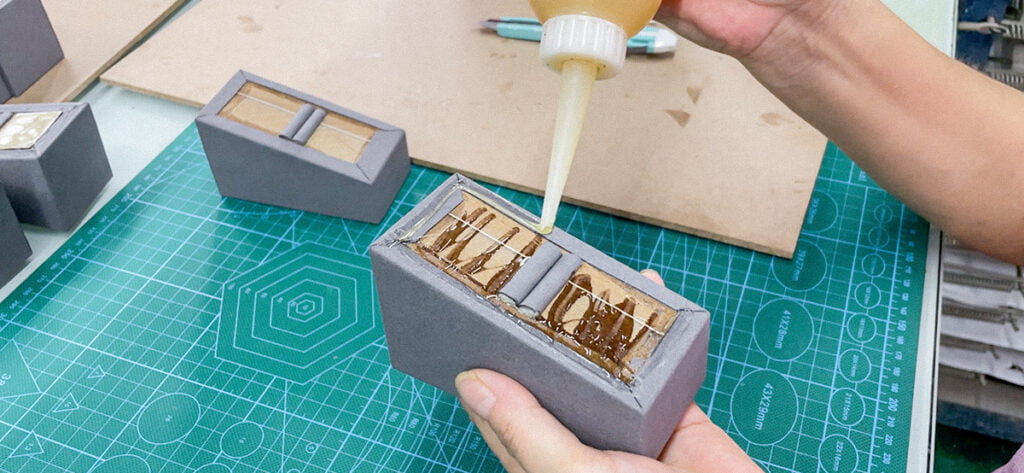

Bonding

For sealing raw edges with trim, or bonding between panels, white emulsion adhesive is generally used.

Engraving

Usually, use MDF for CNC engraving, you can make patterns or curved shapes on its surface. Laser engraving can be considered for making hollow patterns on thin sheets.

Applying veneer

The veneer does not have to be the wood grain of the bark, it can also be a way to save money by applying some metal film, or marble grain film.

What problems often occur in the production of wooden displays?

In the quality control process, we tend to find some common problems that will occur in wooden display racks.

Material moisture deformation

Deformation of the plates by moisture will lead to gaps between the plates if the deformation will affect the appearance of the display rack or even functional problems. Slight deformation of the plates can try to use by the flattening machine, but if the product is required to be not easily deformed, it is recommended to use the plywood that is not easily deformed.

Over-sanding or under-sanding

Over-sanding can deform the panel and give it an uneven, sandy texture, while under-sanding can leave scratches or minor dents in the material itself. Both conditions can lead to poor painting results.

The paint surface is not uniformly bright or dark

The white-painted products and the angular edges of the display frame are easily exposed to the color of the base plate after painting, and they often require two more coats of topcoats during the painting process. Uneven spraying will make the paint surface produce orange peel or tear marks phenomenon. The quality of sanding will also have an impact on the spray paint.

Cracking

If the plate is too dry, drilling, assembling, and cutting may cause the plate to crack and eventually lead to product scrap. Change the tools on time and design the product size properly to reduce the cracking.

Bumping

The damage to the panels or semi-finished products can be caused by irregularities in handling and production. Before painting, the damaged parts can be repaired with a poly-putty base, sanded flat, and then painted.

How to save costs in wood display production?

Veneer

Various styles of wood veneer marbled or other stickers are available on the market. Putting the film on the surface of the panel, treating the edges, and then painting, can create the visual effect of using solid wood, and marble.

Detachable design

Customized display shelf overall transport volume is too large, the cost of transportation will be very high. If the display stand takes disassembled design, it will greatly reduce the transportation cost if it is assembled again when it arrives locally.

What documents are required for import and export?

Some customary necessary documents for import and export, collection of foreign exchange or taxation issues are generally handled entirely by import and export agents. However, due to the special nature of the material, the import and export of wooden display shelves should have some more procedures than other imports and exports.

Fumigation

Fumigation of wood packaging is a mandatory measure to prevent harmful pests and diseases from endangering the forest resources of the importing country.

The requirements and precautions of fumigation

- Wooden packaging shall not have bark.

- The fumigated wooden packaging should be shipped as soon as possible, while attention should be paid to separate storage and isolation from other untreated wood products and wood.

- The validity of the fumigation certificate is 21 days.

- After knowing the packing of the goods, you must ask the shipping agent each time if fumigation is needed and confirm it before booking.

How do take care of wooden displays in daily use?

- Avoid direct sunlight, prolonged sunlight will cause the wood too dry, easy to crack, and local fading.

- Keep the placement environment dry, the wood swells when wet, easy to mold after a long time.

- Reduce bumping, do not let hard metal products or other sharp objects hit the furniture, to protect its surface from hard traces.

- Solid wood display shelves can be sanded and coated with wood wax oil to maintain the luster.

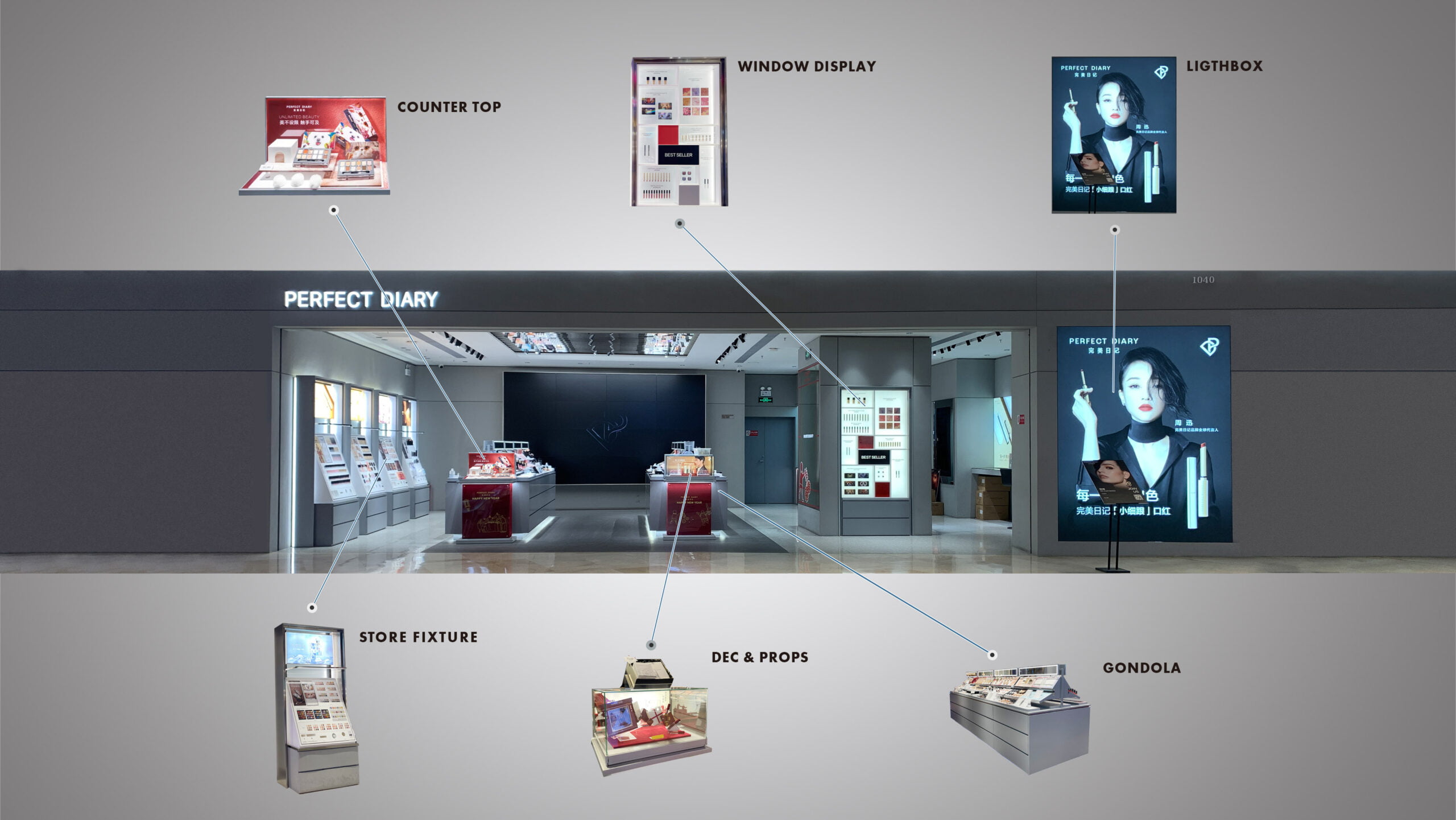

Samtop display has specialized in custom retail solution production, display merchandising consulting for world beauty/perform/eyewear/fashion brands, eg. set up a counter, window display, pop-up store, plvs, product dummy, display maintenance of global counter. Ready to have a new concept? Let’s make it together!