Vacuum Forming for Visual Merchandising

Large-Scale, Durable, High-Gloss Impact displays. Create statement-making windows, brand icons and sculptural fixtures with thick-gauge thermoformed plastics (1.5–13 mm).

Samtop engineers ABS / HIPS / PMMA / PC structures with CNC molds, vacuum forming + pressure assist, and premium finishes — ready for lighting integration and global rollouts.

Our Thermoforming Solutions

One-stop coverage: 3D Design → Molds → Forming → Surface Finishing → Lighting → Installation

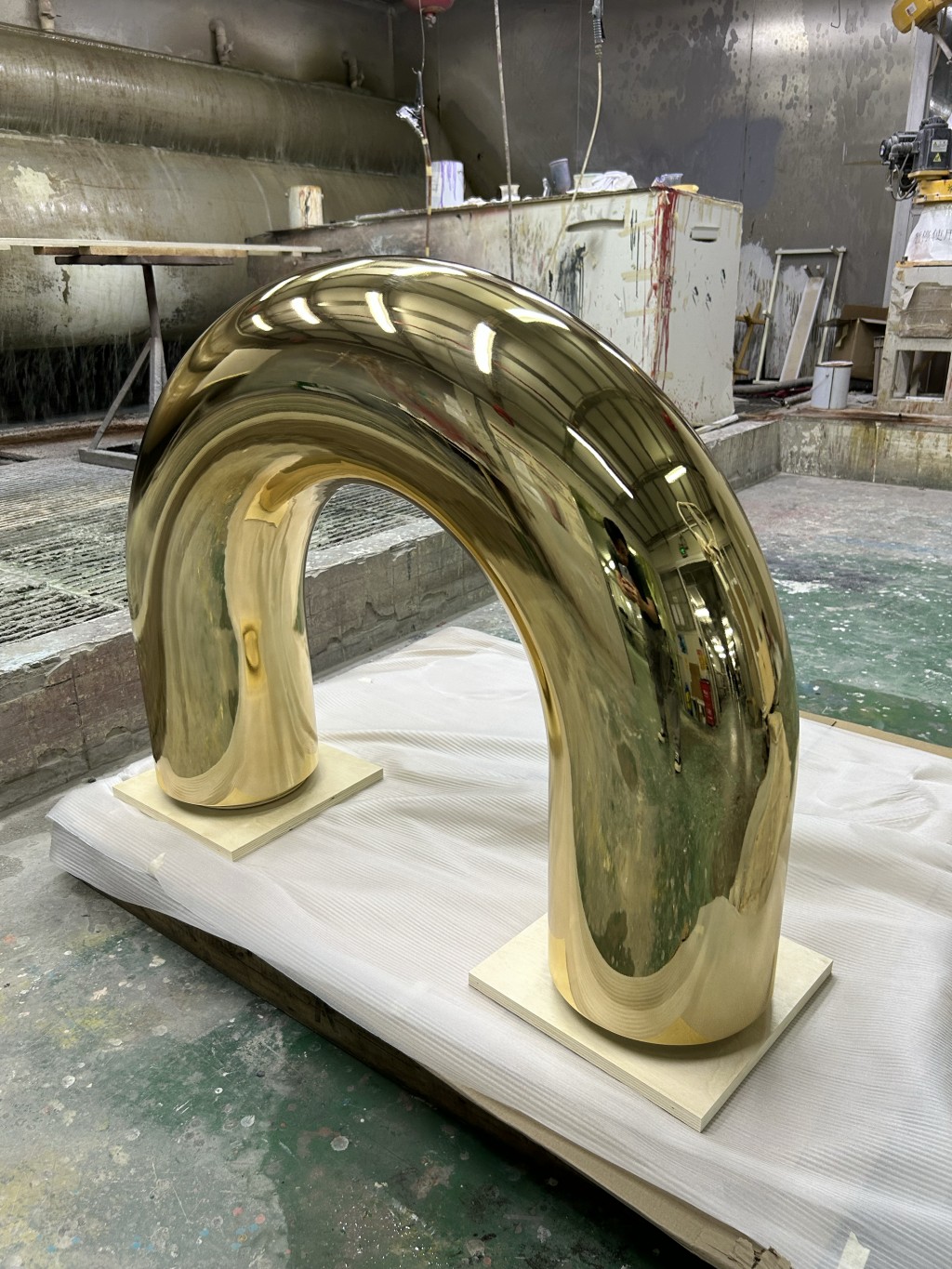

Window & In-Store Sculptures

Large-scale artistic props for windows and interiors: hearts, brand graphics, product silhouettes, curved reliefs.

Backdrops & Relief Panels

Window and counter vacuum-formed backdrops: large 3D reliefs, textured walls, light-transmitting surfaces.

Luminous Structures

Light-transmitting structures with translucent materials and side/back-lighting cavities.

Common Applications

Thick vacuum forming solutions across retail, hospitality, and experiential marketing

Cosmetics Display Backdrops

Premium vacuum-formed backdrops for luxury beauty brand displays

Window Display Backdrops

Large-scale thermoformed window installations for retail environments

Holiday Decorative Props

Seasonal vacuum-formed installations and festive display elements

Valentine's Heart Sculptures

Custom thermoformed romantic displays with premium finish treatments

Promotional Display Props

Eye-catching vacuum metallized displays for marketing campaigns

Pop-up Store Decor

Modular thermoformed experiential displays for luxury brand activations

Materials & Craftsmanship

Premium thermoplastics and advanced finishing systems for luxury visual merchandising

Resins & Typical Use

ABS

Impact-resistant, paintable; great for structural shells and durable installations.

HIPS

Economical, good paintability for large décor and cost-effective solutions.

PMMA (Acrylic)

High gloss, optical clarity; ideal for lit features and premium finishes.

PC (Polycarbonate)

High impact & heat resistance; tougher installs and demanding environments.

Finish Systems

Spray Paints

Matte / gloss / pearl / brushed-metal looks for versatile aesthetic options.

Vacuum Metallization

Gold/silver/colored chrome + UV topcoat for premium metallic finishes.

Films & Transfers

Wrap films, water transfer prints, silkscreen / UV printing for complex graphics.

Thick Vacuum Forming Process

From concept to installation: our comprehensive manufacturing workflow

3D Design & Engineering

Convert VM concept to STP/IGES; plan draft angles, undercuts, split lines, reinforcement, lighting cavities.

Mold Making

Aluminum molds for production; CNC wooden/MDF molds for sampling. Polish & high-temp release coating.

Heating & Forming

ABS 155–165°C, PMMA 170–180°C. Vacuum forming + pressure forming for crisp detail and precision.

Finishing & Assembly

CNC trimming, surface finishing, LED integration, bonding, mechanical fastening, and final QC.

Material Selection Guide

| Vacuum Forming Dimension | Thick Vacuum Forming | Thin Vacuum Forming |

|---|---|---|

| Sheet thickness | 2–13 mm | 0.2–1.5 mm |

| Rigidity | High (self-supporting) | Low (needs support) |

| Part size | Very large (2 m+) | Small to medium inserts |

| Service life | Long-term / reusable | Short-term / disposable |

| Cost | Higher per part | Lower per part |

| Use cases | Structures, large décor, 3D logos | Trays, blisters, light packaging |

Frequently Asked Questions

Thick Vacuum Forming in Visual Merchandising

Request Your Custom Thick Vacuum Formed Display Consultation

CNC Mold Precision

Large-format forming (2 m+) with exceptional detail accuracy for premium display applications

Premium Finishes

Vacuum metallization, pearl effects, and brushed metal expertise for luxury brand requirements

Global Installation

Lighting-ready structures, modular splits, and worldwide installation support for seamless deployment