(Resin | Metal | Lighting | Interactivity | Multi-Year Collaboration)

Partner with over multiple years to create a series of interactive jewelry window displays combining metal, resin, acrylic, and custom lighting.

From the “Heart of Arrows” to “Frozen Gift” and “Water Ripple” themes, each display merges storytelling with engineering precision — showcasing how craftsmanship elevates brand emotion.

Luxury jewelry brands face a creative dilemma — how to make each seasonal window both technically innovative and emotionally resonant.

Each concept must tell a story that aligns with brand heritage while ensuring production feasibility and repeatable quality across global boutiques.

Traditional window designs often fail in interactivity, light control, or structural durability, leading to visual inconsistency between flagship stores and satellite boutiques.

For a brand like Tiffany, every window is a love letter — one that must shimmer flawlessly worldwide.

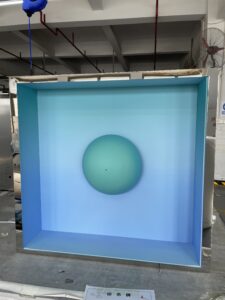

Samtop Display collaborated with Tiffany & Co. on a multi-year series of custom window installations, integrating resin sculpture, metal fabrication, optical lighting, and structural engineering to bring poetic narratives to life.

Each year’s display — whether depicting Cupid’s heart, crystalized gift boxes, or rippling light reflections — was engineered for precision, durability, and emotional impact.

🏗️ Engineering Overview

Project Type: Seasonal Window Display Series

Techniques: Resin casting, CNC metal, laser engraving, LED diffusion, interactive light systems

🎨 Design & Concept Themes

| Theme | Concept Message | Key Material | |

|---|---|---|---|

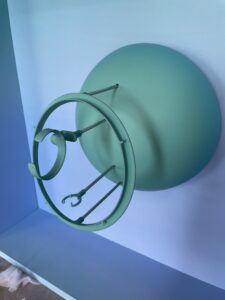

| 💘 Heart of Arrows | Love as the central force — arrows converge toward the heart | Resin sculpted heart + metal arrows | |

| 🎁 Frozen Gift | Time freezes at the moment of surprise | Transparent resin gift box + fiber optic LED | |

| 💧 Rippling Water | Love creates ripples of emotion | Cast acrylic water surface + reflective metal | |

| ✨ Interactive Light Window | Jewelry radiates movement and connection | LED motion sensors + gradient panels |

Technical Process Breakdown

1️⃣ Concept Engineering & 3D CAD Design

Each window started with parametric CAD modeling to simulate shadow angles, LED diffusion, and assembly balance.

The engineering team validated structural stability under high temperature + humidity for global store consistency.

2️⃣ Resin Craft & Precision Casting

-

High-transparency resin was vacuum cast and polished to crystal-like clarity.

-

For the Frozen Gift, micro-bubble resin layering mimicked ice crystallization.

-

Each heart or ripple module was reinforced internally with stainless steel armature.

3️⃣ Metal Fabrication & Surface Finish

-

CNC-cut arrows, brushed and electroplated in matte champagne silver.

-

Metal trims were designed with 0.1mm tolerance for seamless glass integration.

-

Polished edge frames reflected ambient light for a halo effect.

4️⃣ Lighting System Integration

-

Embedded LED light panels with dimmable color temperature (2700–6500K).