Engineering drawings for POP displays are essential before mass production. At Samtop, we provide full technical blueprints for visual merchandising. These include dimensions, materials, structure, exploded views, electronics layout, and more to ensure custom displays are accurate, stable, and factory-ready.

You’ve approved a 3D rendering. You love the mockup.

But before making hundreds of units, you ask:

“Can we see the engineering drawing first?”

- Parts that don’t align

- LED placement errors

- Weak or fragile construction

- Packaging that doesn’t fit

- Confused in-store assembly

Our engineering drawings for POP displays ensure every detail is ready for mass production, from LED layout to assembly steps.

✅ What’s Included in Our Engineering Drawings for POP Displays

| Detail | Purpose |

|---|---|

| 📏 Dimensions (mm/in) | Confirm fit in-store / shelf / window |

| 🔧 Assembly logic | Show screw / magnet / snap-fit joinery |

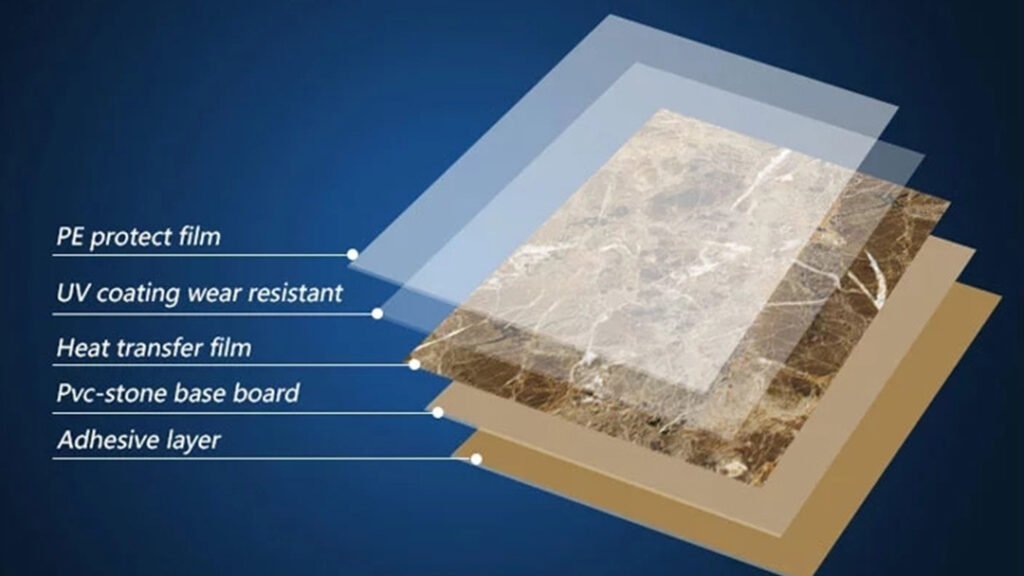

| 🧱 Material breakdown | Label acrylic, MDF, foam, metal |

| 🔌 Electronics layout | LED strips, wiring, battery placement |

| 📦 Packaging view | Optional flat-pack/crate plan |

| 🔩 Exploded view | Clarify component relationships |

💡 These drawings = blueprint for factory, packers, installers, and clients.

📐 3D Rendering vs Engineering Drawing

| 3D Rendering | Engineering Drawing |

|---|---|

| Visual, stylized | Structural, functional |

| Made for approvals | Made for production |

| Often lacks logic | Shows tolerances, connections, materials |

| Provided by designer | Engineered by Samtop CAD team |

🔧 Our POP Display Drawing Workflow

| Stage | What You Receive |

|---|---|

| Quote stage | Optional size sketch (on request) |

| Sampling stage | Full CAD + exploded view |

| Before production | Final file for approval |

| Post-sample update | Optional revision with real-world refinements |

✅ You approve drawings before mass production starts.

💬 Real Client Example: LED Beauty Tray

Client provided only visual mockup. Samtop delivered:

- Exploded view

- LED wire route

- Acrylic thickness specs

- Anti-slip pad layout

🎯 Result: “No corrections needed — production went perfectly.”

Clients often request engineering drawings for POP displays before committing to bulk orders, and we deliver complete CAD plans.

📦 Optional Add-Ons (by request)

| Add-on Item | Why It Helps |

|---|---|

| 🧩 Die-cut insert plan | For packaging / filler foam |

| 🧾 Logo print layout | Precise branding alignment |

| 📱 QR assembly diagram | Easy install for rollout teams |

| 📸 CAD vs real photos | Validation between sample and plan |

| 📉 Volume & logistics data | Helps plan shipment size + crate usage |

🧠 Who Needs Engineering Drawings the Most?

- 💼 Procurement teams

- 🧠 Designers / visual creatives

- 🛍️ Retail VM departments

- 🛠️ Store fixture teams

- 🔌 Marketing/branding teams

🎯 Conclusion: Engineering Drawings = Confidence Before Production

At Samtop, we engineer every display for reliability and efficiency.

✔️ No surprises

✔️ No rework

✔️ No blind approvals

✔️ Fully verified by design and production teams