How Samtop Combined ABS Injection, Rotational Molding, Metalwork, and Lighting Craft to Create Sculptural Retail Windows

Samtop Display engineered and produced Mango’s sculptural window display system, combining ABS injection molding, rotational molding, metal fabrication, artistic coating, and integrated lighting.

The result is a refined and modular retail display series that merges industrial precision with artistic texture, achieving Mango’s minimalist yet architectural brand aesthetic.

Mango’s visual merchandising direction emphasizes sculptural simplicity and luminous form — organic yet structured.

The challenge: create large-scale modular decorative units with precise curvature, consistent surface finish, and integrated LED lighting, all suitable for long-term global rollout.

Samtop was commissioned to:

-

Translate Mango’s concept into 3D engineering drawings.

-

Develop manufacturable molds for ABS, metal, and lighting systems.

-

Control surface texture, color, and light diffusion across all components.

-

Deliver a modular system that could be reused and adapted for multiple seasons.

⚙️ The Challenge

The project required integrating industrial manufacturing with artistic surface treatment:

-

Complex geometry that needed tight dimensional control.

-

Multiple materials (plastic, metal, lighting) that had to align perfectly.

-

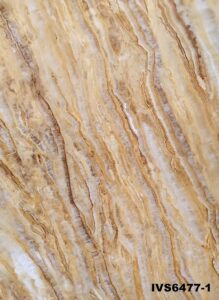

Color and texture harmony across marble, matte, and wooden finishes.

-

Durability for repeated installations in different climates.

Engineering and production team developed a complete workflow — from digital modeling to mass production — ensuring precision at every step.

🧩 Design & Engineering Phase

-

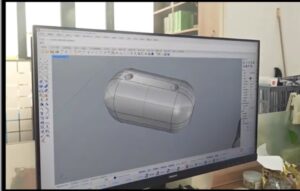

Imported Mango’s design sketch into Rhino 3D for structural development.

-

Built 3D solid models for the main body, base, and lighting units.

-

Adjusted curves and wall thickness for optimal mold flow & structural stability.

-

Designed mold split lines and ultrasonic welding points for seamless assembly.

🏭 Material & Process Integration

| Step | Process | Description |

|---|---|---|

| 1. 3D Engineering Drawings | CAD + Rhino Modeling | Optimized for mold flow, assembly precision |

| 2. ABS Injection Molding | Main body production | Created uniform, lightweight shells with ±0.2 mm tolerance |

| 3. Ultrasonic Welding | Internal joint fixing | Ensured invisible seams and structural strength |

| 4. Artistic Coating | Hand-spray matte & textured finishes | Applied water-based PU paint with soft-touch finish |

| 5. Hydrographic Transfer | Marble & woodgrain surface | Water transfer printing for realistic stone/wood effect |

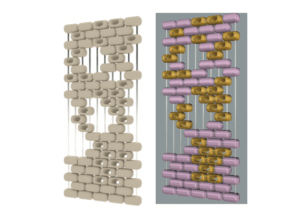

| 6. Rotational Molding (滚塑) | Large hollow elements | Low-density polyethylene for thick-walled sculptural blocks |

| 7. Metal Fabrication | Internal frame & base | CNC-cut steel parts, sanded, powder-coated |

| 8. Light Tube Production | Custom LED tube integration | Soft 6500K diffusion with uniform luminance |

| 9. Lighting Test & Assembly | Electrical validation | Color temperature & brightness matched to Mango standards |

✨ Craft Highlights

1️⃣ ABS Injection & Ultrasonic Welding

The main sculptural components were made through ABS injection molding, then bonded using ultrasonic welding to achieve a seamless exterior.

This ensured precision alignment and reduced manual finishing.

2️⃣ Artistic Surface Treatment

Samtop developed multiple finishes to meet Mango’s visual direction:

-

Matte ivory coating using water-based PU.