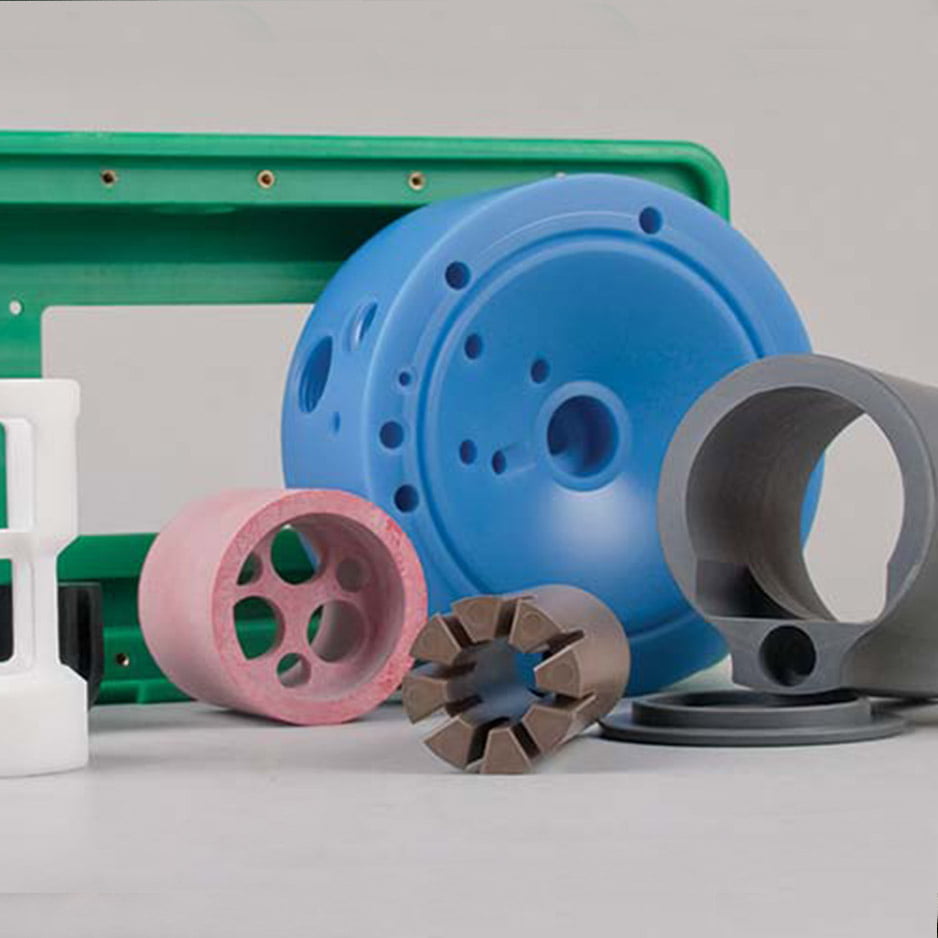

Custom displays have a range of colors, shapes, textures, patterns, lighting, and other elements tailored to the product or brand to bring a different sensory experience to potential customers. In the process of making retail displays, we will choose different production materials according to the different display purposes. The total number of material categories is also relatively large, mainly divided into 3 categories: plastic, wood, and metal.

This article focuses on the general category of plastic often used in retail displays.

Acrylic

Acrylic is the plastic sheet we use most in retail display production. It is strong, hard, transparent, and available in a wide range of colors and thicknesses. It has superior weathering properties compared to other plastic materials, is easy to fabricate, binds well to adhesives and solvents, is easy to thermoform, and is easy to clean during use. From durable signs to retail fixtures, displays, and shelving, acrylic excels at everything.

Acrylic is generally used for small, delicate countertop displays, which are not as strong as metal as well as wood panels but can be used as components in large display cases.

PETG(Polyethylene terephthalate glycol)

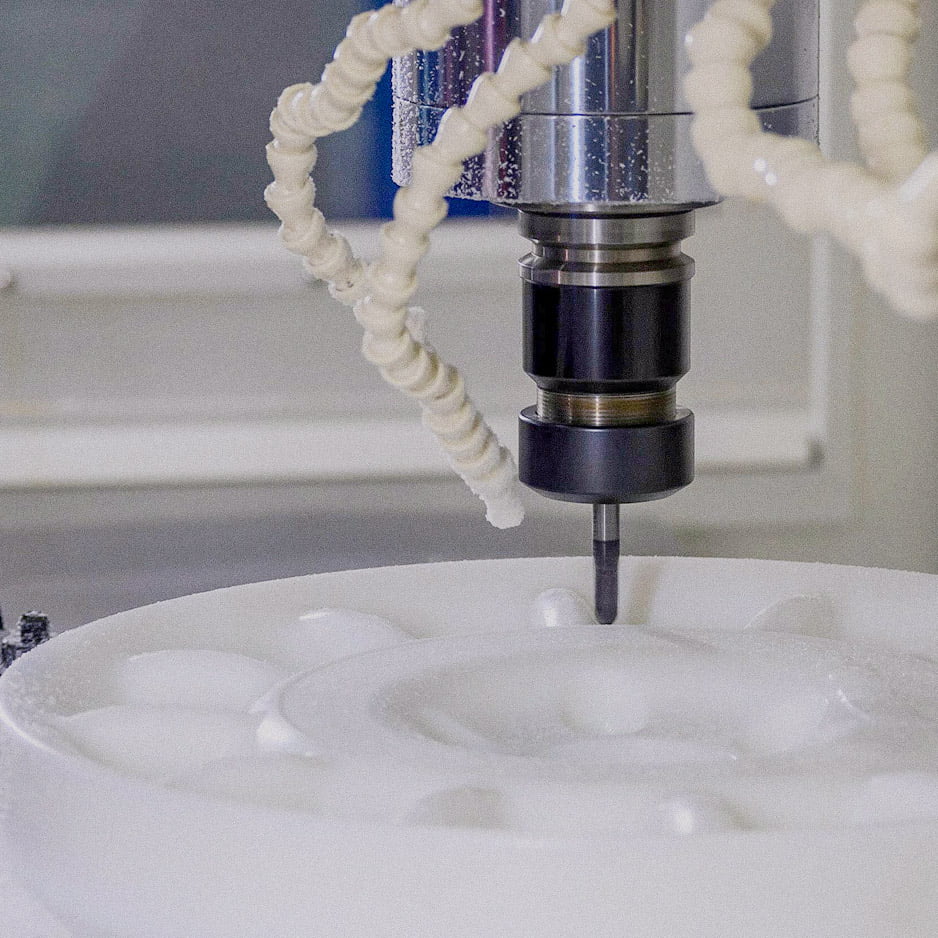

PETG has remarkable chemical properties, durability, and excellent molding properties, it has better toughness than acrylic and will not break and produce cracks after bending many times. PETG is low-temperature molding, so it is suitable for vacuum blistering and thermoforming, it is more widely used than acrylic, but the price is also higher. We use PETG for custom price strips on shelves or other special shapes that require a large degree of deformation.

Expanded PVC foam

Expanded foam is a lightweight but impact-resistant, inexpensive board that is easy to process. It can easily be sawed, stamped, punched, die-cut, sanded, drilled, screwed, nailed, riveted, or bonded using PVC adhesives and is suitable for display boards, POP displays, or as a reinforcing board inside display cases. A perfect substitute for wood.

It is important to note that neither the foam nor the PVC film can be cut by laser, as the cross-section will be scorched and yellowed by the laser.