A Step-by-Step Guide to Ensuring Quality Before Mass Production

By Yan Luo | Samtop Display

A pre-production sample (PPS) is a critical checkpoint in custom display production, ensuring your retail display aligns with design files, functionality, and brand standards before mass manufacturing.

At Samtop, we help brands streamline the PPS review process—ensuring every detail is verified before production ramps up.

You’ve approved the design, paid the deposit, and now production is starting—only to realize the final product has material issues or doesn’t match your visual standards.

A missed error in color, dimensions, or functionality can lead to hundreds of incorrect units, wasted budget, and brand inconsistency.

A clear and structured PPS (Pre-Production Sample) review process lets you spot and fix errors before mass production—protecting your quality, timeline, and reputation.

📊 Quick Comparison: PPS Checklist Overview

| Review Step | What to Check | Key Benefit | Tip |

|---|---|---|---|

| Submit Clear Specs | Files, materials, tolerances | Sets the foundation | Include Pantone, dimensions, finish types |

| Set Sample Expectations | Design approval, function testing | Aligns with production goals | Confirm timeline and use cases |

| Review Physical Sample | Dimensions, finish, functionality | Catch errors early | Compare under natural/store lighting |

| Collect Team Feedback | Branding, durability, usability | Gets all stakeholders aligned | Include retail staff if possible |

| Approve or Revise | Adjust and re-sample as needed | Prevents costly mass production mistakes | Request new PPS if changes are major |

🛠️ What Is a Pre-Production Sample (PPS) and Why It Matters

A PPS is the first physical prototype built by your supplier based on the approved design. It is used to:

- ✅ Validate design accuracy

- ✅ Test functionality and performance

- ✅ Review brand aesthetics and materials

Think of the PPS as your final opportunity to inspect and adjust before committing to mass production.

📦 Step 1: Submit Detailed Specifications

Include in your request:

- 📐 Design Files: CAD, STL, AI, or PDF with dimensions and structure.

- 🎨 Color Codes: Use Pantone references or hex values.

- 🧱 Material & Finish: Glossy, matte, textured, or metallic.

- ➕ Functionality Requirements: Lights, motion, interactivity.

- 📏 Tolerances: Define exact variance allowances (e.g., ±0.2mm).

Tip: Attach a branded style guide and reference samples to reduce guesswork.

🧭 Step 2: Define PPS Goals and Timeline

Clarify with your manufacturer:

- 🔧 Is the sample for functionality testing (e.g., light, sensors)?

- 🎨 Is it for visual inspection only?

- 📅 What is the deadline to receive the PPS?

Tip: Always specify whether the sample is final or still iterative.

🔍 Step 3: Review the PPS Like a Pro

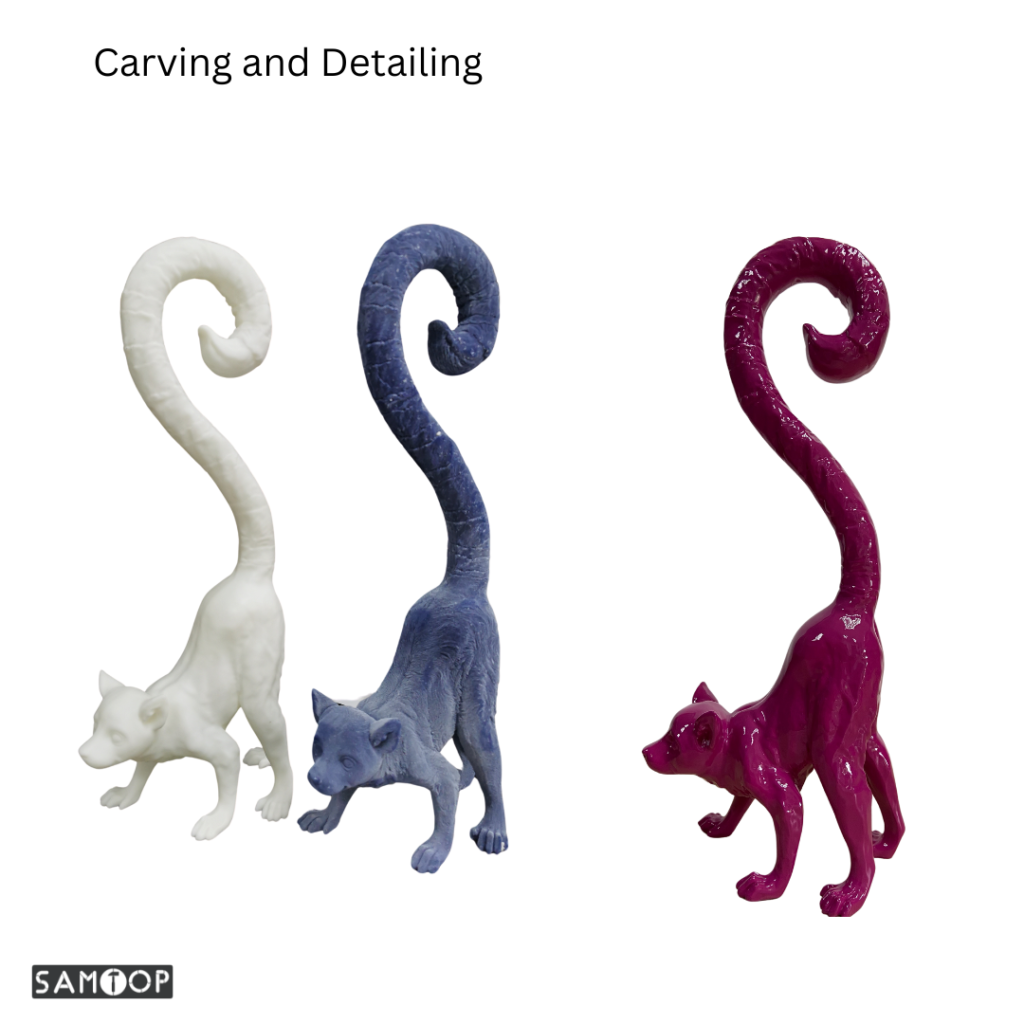

Review the pre-production sample (PPS) carefully for dimensions, color accuracy, and finish consistency.

✅ Design & Aesthetic Accuracy

- 📏 Check dimensions with calipers or rulers.

- 🎨 Match color with Pantone chips under neutral lighting.

- 🧱 Feel material texture and finish—is it consistent?

✅ Functionality & Durability

- 🔋 Test battery packs, LED lights, or motors.

- 🧪 Stress-test moving parts and joints.

- 💧 Consider moisture, UV, or heat if the display is outdoors.

Tip: Simulate the real retail environment—including lighting, customer interaction, and shelf pressure.

👥 Step 4: Get Internal & External Feedback

Involve: