When brands create retail POP fixtures, one of the most common questions we receive is:

“How can we print patterns, logos, or text on acrylic displays?”

Choosing the right method of printing on acrylic displays directly affects color accuracy, durability, and the premium look of your final retail prop. Below is a complete guide to the most widely used printing technologies in the POP display industry—including when to use each one.

Why Printing on Acrylic Displays Matters

Acrylic is one of the most popular materials for POP displays because of its clarity, high-end appearance, and ability to be shaped, polished, and illuminated. However, acrylic also requires the right printing method to ensure:

-

Sharp logo visibility

-

Long-lasting color

-

Scratch resistance

-

Smooth gradients or fine details

-

Compatibility with lighting (LED glow, backlit effects)

Now let’s break down the three most common and effective methods of printing on acrylic displays.

1. UV Printing on Acrylic Displays

UV printing is the most popular technique for acrylic displays today. It offers excellent visual performance and versatility.

How UV Printing Works

UV printers use ultraviolet light to cure ink instantly as it is applied to the acrylic surface. This results in:

-

Bright, vibrant color

-

Sharp, high-resolution graphics

-

Multi-color and gradient capability

-

Good durability for indoor use

When to Use UV Printing

UV printing is ideal for:

-

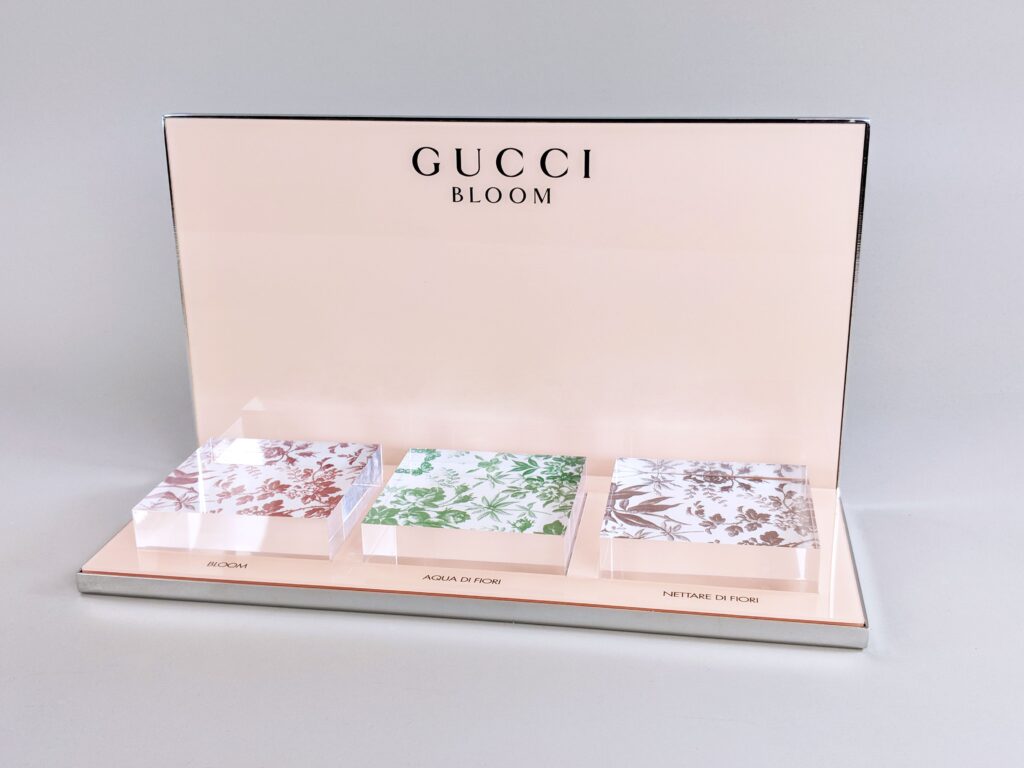

Perfume glorifiers

-

Tester trays

-

Logo panels

-

Back panels with gradient artwork

-

Multi-color imagery

-

Small or medium production runs

Limitations of UV Printing

-

Not recommended for outdoor use with direct heat exposure

-

On colored acrylic, you must print a white ink base before printing graphics

-

Slight color deviation may occur depending on acrylic tone

-

Extremely high heat (spotlight flare) may cause ink weakening

Examples

UV printing is widely used for fragrance displays, skincare trays, and cosmetics tester units.

2. Screen Printing on Acrylic Displays

Screen printing is a traditional and highly durable technique, perfect for simple artwork and solid colors.

How Screen Printing Works

A mesh “screen” is created with your artwork. Ink is pressed through the stencil onto the acrylic surface.

Advantages of Screen Printing

-

Very stable color

-

Extremely durable

-

Perfect for logos and solid-color artwork

Visual Merchandising Solutions

Transform your retail space with custom POP displays, window decorations, and luxury merchandising solutions. Get expert consultation and premium manufacturing services.

Cost-effective for large batches

No risk of banding or pixelation

Limitations

-

One color per screen → multi-color printing becomes complex

-

Requires highly skilled technicians for alignment

-

Not suitable for gradients or photographic images

-

Only suitable for flat surfaces—concave or textured surfaces may cause broken lines

-

High setup cost for small quantities

Best Use Cases

-

Logo printing

-

Simple icons

-

Single-color text

-

Large batch production

3. Heat Transfer Printing on Acrylic Displays

Heat transfer is a flexible method ideal for artwork requiring multiple colors or complex graphics.

How Heat Transfer Works

-

Your graphic is printed onto transfer film

-

Heat and pressure transfer the artwork onto the acrylic

-

A protective film layer adheres to the surface

Advantages

-

Good for multi-color artwork

-

Can apply detailed designs

-

Works well for curved areas (more flexible than screen printing)

-

Vibrant finish

Limitations

-

Less durable than UV or screen printing

-

Film edges may be visible

-

Not ideal for luxury fixtures requiring a seamless look

Best Use Cases

-

Promotional displays

-

Multi-graphic low-cost campaigns

-

Curved or complex shapes

Which Printing Method Should You Choose?

| Requirement | Best Method | Reason |

|---|---|---|

| High-end, premium visuals | UV Printing | Gradient & high res |

| Long-lasting solid logos | Screen Printing | Most durable colors |

| Multi-pattern, budget-friendly | Heat Transfer | Low-cost, flexible |

| Short lead time | UV Printing | No plate making |

| Large quantity runs | Screen Printing | Cost efficiency |

Every method of printing on acrylic displays has its purpose—your choice depends on durability needs, color requirements, and project budget.

Conclusion: Choose the Right Printing Method for Stronger Brand Impact

Whether you need vibrant gradients, long-lasting logos, or cost-effective multi-color patterns, understanding the methods of printing on acrylic displays helps you make the right manufacturing decision.

At Samtop Display, we help brands choose the best process based on:

✔ Visual requirements

✔ Acrylic color & finish

✔ Durability expectations

✔ Budget & production volume

✔ Retail display lighting conditions

Want expert advice on which method is best for your project?

📩 Contact us anytime — we’re here to support your next display build.