Samtop’s Timeline Guide for Successful Holiday Visual Campaigns

Start sourcing custom Christmas window props in July, approve samples by August, begin production in September, and ship by October — to ensure smooth in-store setup by early November.

Wondering when to start planning your Christmas retail displays?

Here’s the ideal timeline for sourcing custom window props and decorations:

- June–July → Concept planning, theme & sketches

- July–August → Quotation, material selection, design approval

- August → Sample production & approval

- Sept–Early Oct → Mass production (resin, LED, foam, fiberglass)

- October → Shipments by sea (30 days) or air (5–10 days)

- Early–Mid November → In-store setup before Black Friday

💡 Start early to unlock more design freedom and avoid air freight costs.

🎯 Introduction: Holiday Displays Don’t Wait for December

You walk past a boutique in early November...

There it is — glittering snowflakes, giant gift boxes, red & gold candy canes, shimmering lights.

What many people don’t see is this:

That Christmas window was planned 4–6 months earlier.

If you're responsible for visual merchandising, one question matters:

👉 “When should I start sourcing Christmas window display props and decorations?”

At Samtop, we produce custom holiday props for global luxury brands — from candy sculptures to LED light arches and foam installations.

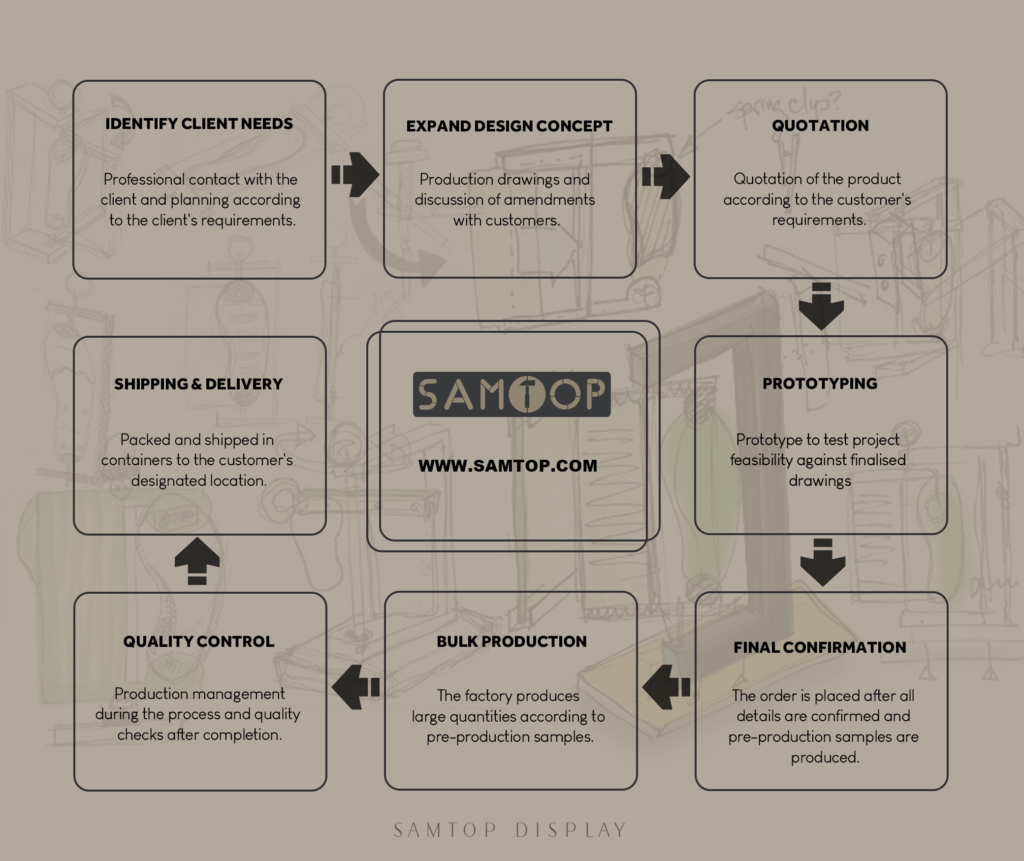

Here’s the ideal production timeline — and what risks you take if you start too late.

✅ Christmas Window Prop Sourcing Timeline (Structured Table)

| Stage | Timeframe | Activities |

|---|---|---|

| 🎨 Concept Planning | June–July | Moodboard, theme, sketches, references |

| 📐 Quotation & Design | July–August | Confirm size, materials, renderings |

| 🧪 Sample Approval | August | Color panel, print/logo tests |

| 🏭 Production | Sept–Early Oct | Resin, foam, fiberglass, LED work |

| 🚛 Shipping | October | Sea: 30–40 days; Air: 5–10 days |

| 🎄 In-Store Setup | Early–Mid November | Global rollout done before Black Friday |

💡✅ Tip: Start early to unlock more creative flexibility and avoid air freight costs.

🎁 Why Christmas Props Take Time to Produce

Most high-end props are custom-made, requiring:

They often involve:

- 🧊 Fiberglass sculptures (trees, reindeer, sleighs)

- 🍭 Foam props (candy canes, stars, snowmen)

- 💡 LED signage / arches / bases

- 💎 Mirror acrylic snowflakes or ornaments

- 🌸 Paper flower walls in festive colors

- 🎁 Luxury gift boxes with logo print / UV ribbon

Each one takes time to:

- Molding, flocking, drying

- Color matching to Pantone

- Glitter coating / mirror finish

- LED integration + pretesting

- Protective packaging with foam/crate

🚫 What Happens If You Start Too Late?

| Risk | What Happens |

|---|---|

| ❌ Material limits | No chrome / mirror / velvet finishes |

| ❌ No sampling time | Wrong logo size, color, texture surprises |

| ❌ Missed factory slot | Others already booked for Christmas |

| ❌ Expensive logistics | Forced to ship by air ($$$) |

| ❌ Miss Black Friday | Sales window shrinks |

💡 The earlier you book your slot, the more stable your rollout.

📦 Smart Brands Use Staggered Sourcing Plans

| Market | Recommended Ship | Planning Start |

|---|---|---|

| 🇺🇸 North America | Mid October | July |

| 🇪🇺 Europe | Late October | July |

| 🇭🇰 Asia / Duty Free | Early November | August |

| 🇫🇷 Flagship Boutiques | Early–Mid Nov | June |

| 🎄 Holiday Pop-ups | Early Nov | August |

🧠 Want to reuse last year’s prop frame? Ask us to re-coat it with new themes.