In retail displays, wood is often used to build an overall structure for the display. Large wall displays, gondolas in the center of the store, and decorations in the store all use wood. In our long-term production display work, the most commonly used woods are the following.

MDF

The most commonly used board in retail displays is a board made of wood fiber with resin by heating and pressing. It has high density and strength, a smooth surface, and easy processing, and can be carved. Whether it is a large permanent display or a small display placed on the counter, almost all use MDF.

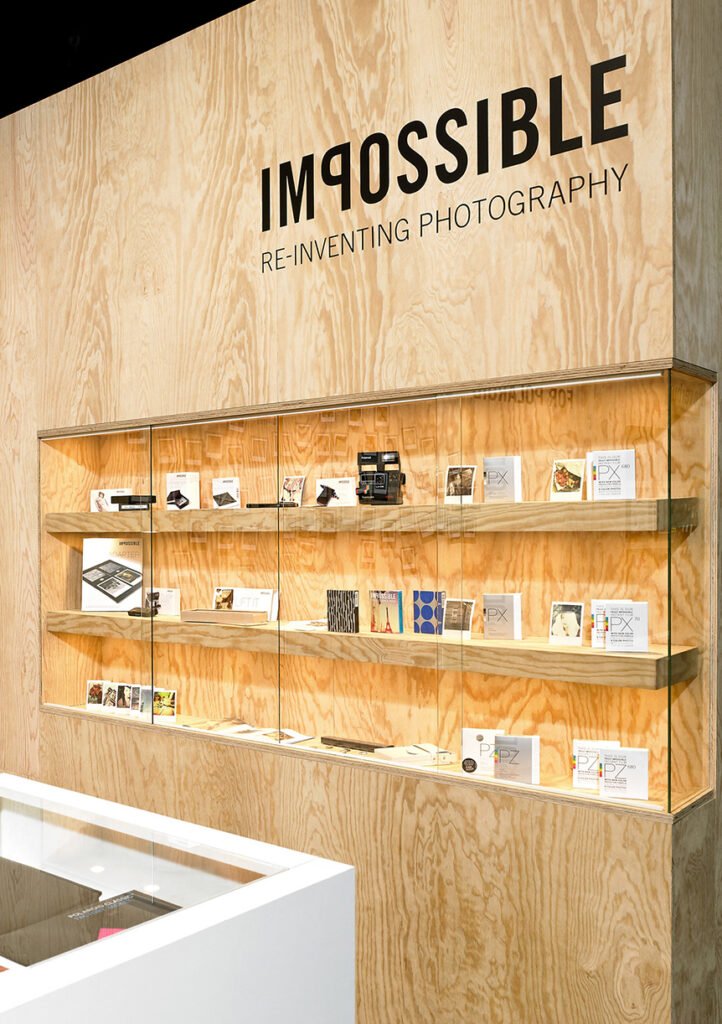

Plywood

The wooden board is made of several layers of thin wood fibers arranged vertically in the direction of bonding, hardness, and grip nail strength, suitable for the production of large store display backboards and bottom boards. Its cross-section is easy to produce burst teeth when cutting and requires high processing equipment. Plywood has different grades, if you use secondary plywood to do display is easy to deform crack.

Particle board

Particle board, also known as chipboard, is a type of engineered wood product that is made by combining wood particles or chips with a synthetic resin or adhesive binder. It is easy to burst when cutting. The cross-section must be sealed, in addition, particle board is susceptible to moisture expansion, is not environmentally friendly, has poor stability, nail grip is not strong, but the price is cheap.

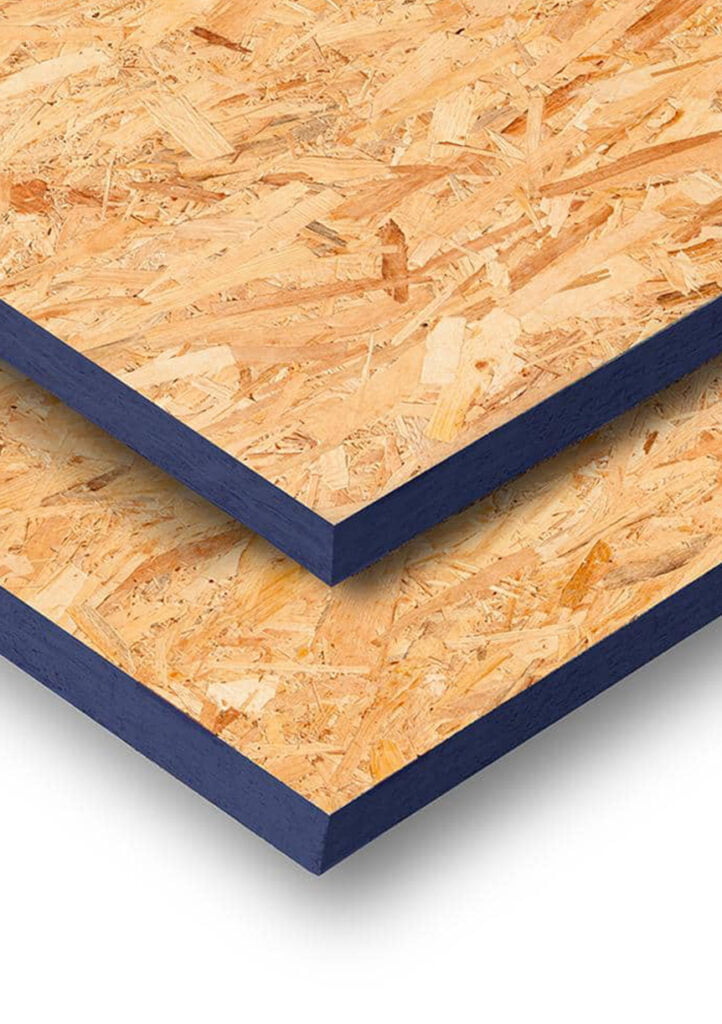

Oriented Strand Board(OSB)

It is made of long, thin, oriented wood slices, which are heated and pressed after adding synthetic resin or adhesive binder. The grain pattern of OSB is particularly easy to recognize, and the internal bonding strength is high, with no joints or gaps, strong nail grip, and low price. Young trendy stores will directly use the appearance of the untreated OSB.

Solid wood

Solid wood has a natural wood grain that everyone prefers, and Eco-friendly luxury brands or vintage-style stores will use solid wood. Solid wood is environmentally friendly but expensive, easy to out of shape, and not suitable for placement in a too-wet or too-dry environment, the export needs to be fumigated and disinfected.