Smart SKU Consolidation to Cut Display Costs Without Compromising Design

Yes, you can combine different retail display designs into one production run — if they share core structures. This saves 15–30% in tooling, labor, and packaging costs. Samtop shares how to consolidate smartly and keep QC tight.

🎯More SKUs, More Complexity — Or Is It?Planning a retail campaign with multiple display types?

One version for skincare, another for fragrance.

LED in flagship stores, printed logo in outlets.

Multilingual markets, regional branding — all at once.

Now you're asking:

"Can I combine these into one production run to save cost?"

Good news: Yes — and it's what Samtop does best.

We help brands save 15–30% by consolidating variations through modular engineering — keeping visual differentiation without multiplying cost.

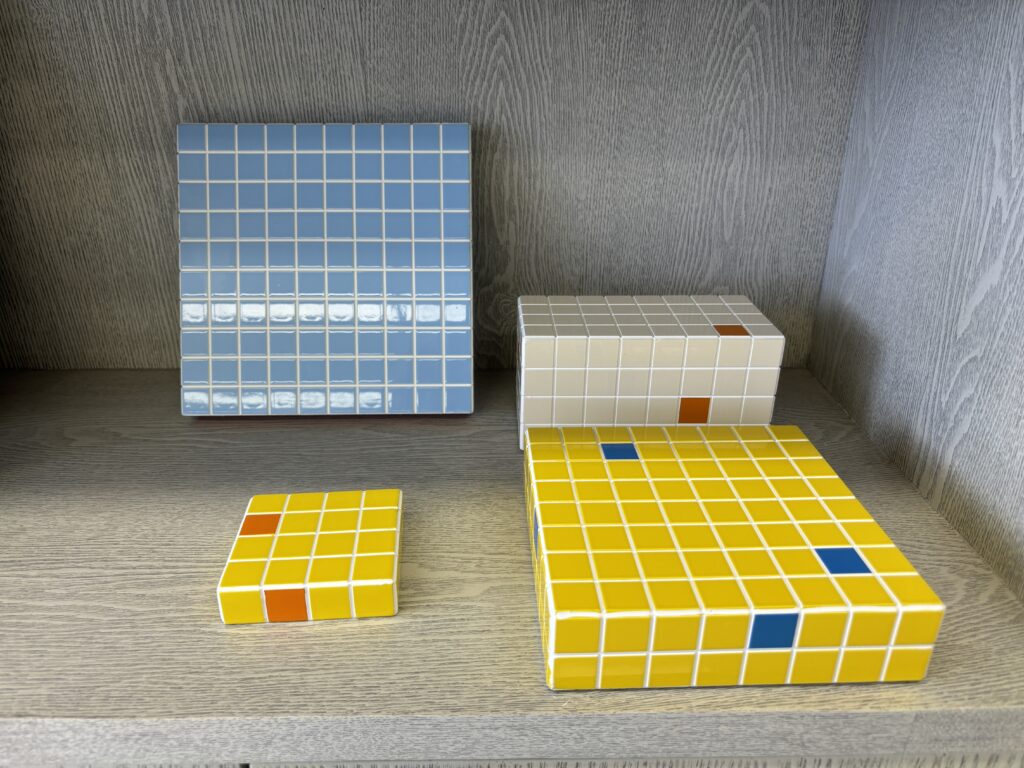

When to Combine Display Designs

| Shared Element | Allowed Variation Examples |

|---|---|

| Structure | Same mold, size, material |

| Printing | Different logo, tagline |

| Color | Different paints, same process |

| Inserts | New tray layout, shared base |

| Add-ons | LED optional, sign topper changes |

💡 Rule of Thumb: If 60–70% is shared, consolidate.

❌ When NOT to Combine

| Factor | Risk |

|---|---|

| Totally different molds | No packaging/tooling benefit |

| Materials change (ABS vs acrylic) | Sourcing & QC complexity |

| Too many SKUs (6+) | Difficult version tracking |

| Version-specific electronics | Inconsistent wiring, QC fails |

🔍 Samtop provides merge feasibility reports before production.

💡 💰 Case Study: How to Combine Display Designs and Save 21%

| Version | Specs |

|---|---|

| A | LED + gold finish + Logo A |

| B | No LED + silver + Logo B |

| C | Same mold, new tray layout |

🧠 Shared by Samtop:

- Mold & assembly process

- Packaging foam & size

- Color-coded labeling

✅ Result: Saved 21% on cost + unified shipping across 9 markets.

🛠️ What Can Be Shared to Save Cost?

| Part of Display | Shared When… |

|---|---|

| Main body | Mold/cut shape is identical |

| Materials | Same type, finish, thickness |

| Painting / printing | Only colors or logos differ |

| Packaging | Shared box size — version labeled separately |

| Assembly process | No need for multiple setups or retraining |

✅ Samtop applies version ID labeling & batch tracking for clarity.

📦 What You Should Send Us

To determine if versions can be batched:

- All design files or mockups (PDF or 3D)

- Quantity per version

- Launch timeline and destination markets

- List of variation points

- Any special finish or LED usage

We’ll provide:

- Merge feasibility report

- Side-by-side cost: separate vs combined

- Packaging strategy: by region, SKU, or warehouse

🧠 Pro Tip: Use Modular Strategy to Combine SKU Display Designs for Cost Control

| Tier | Strategy Example |

|---|---|

| Flagship | Full LED, premium finish, enhanced branding |

| A-store | Partial LED, standard finish |

| B-store | No LED, simpler structure, same base |

| Travel retail | Smaller version, reduced component count |

🎯 1 mold, multiple expressions = consistent brand + lower cost

🎯 Conclusion: Combine Smart, Save More

More versions ≠ more complexity — if you plan modularly.

Samtop helps you: